Back to Courses

Mechanical Engineering Courses - Page 11

Showing results 101-110 of 148

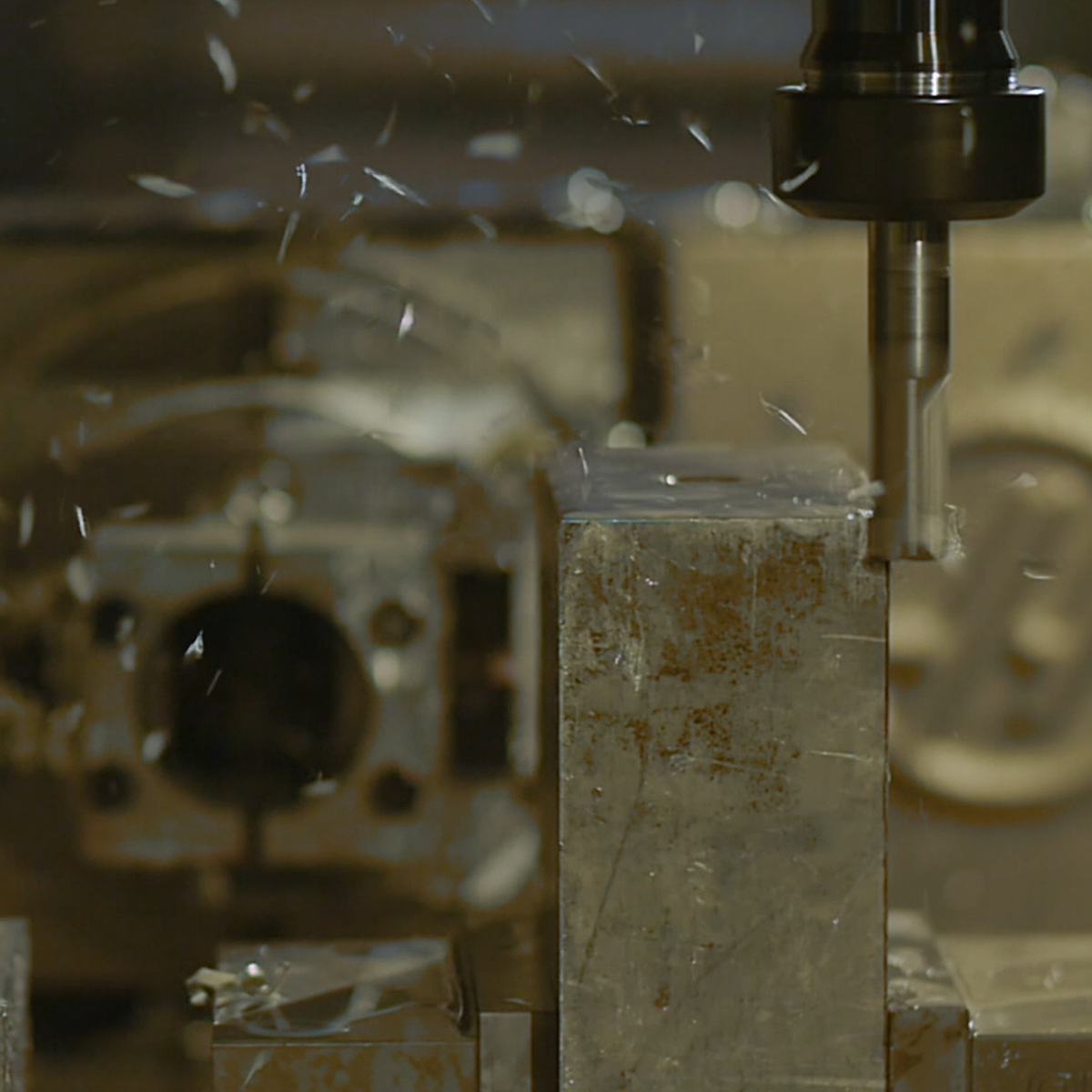

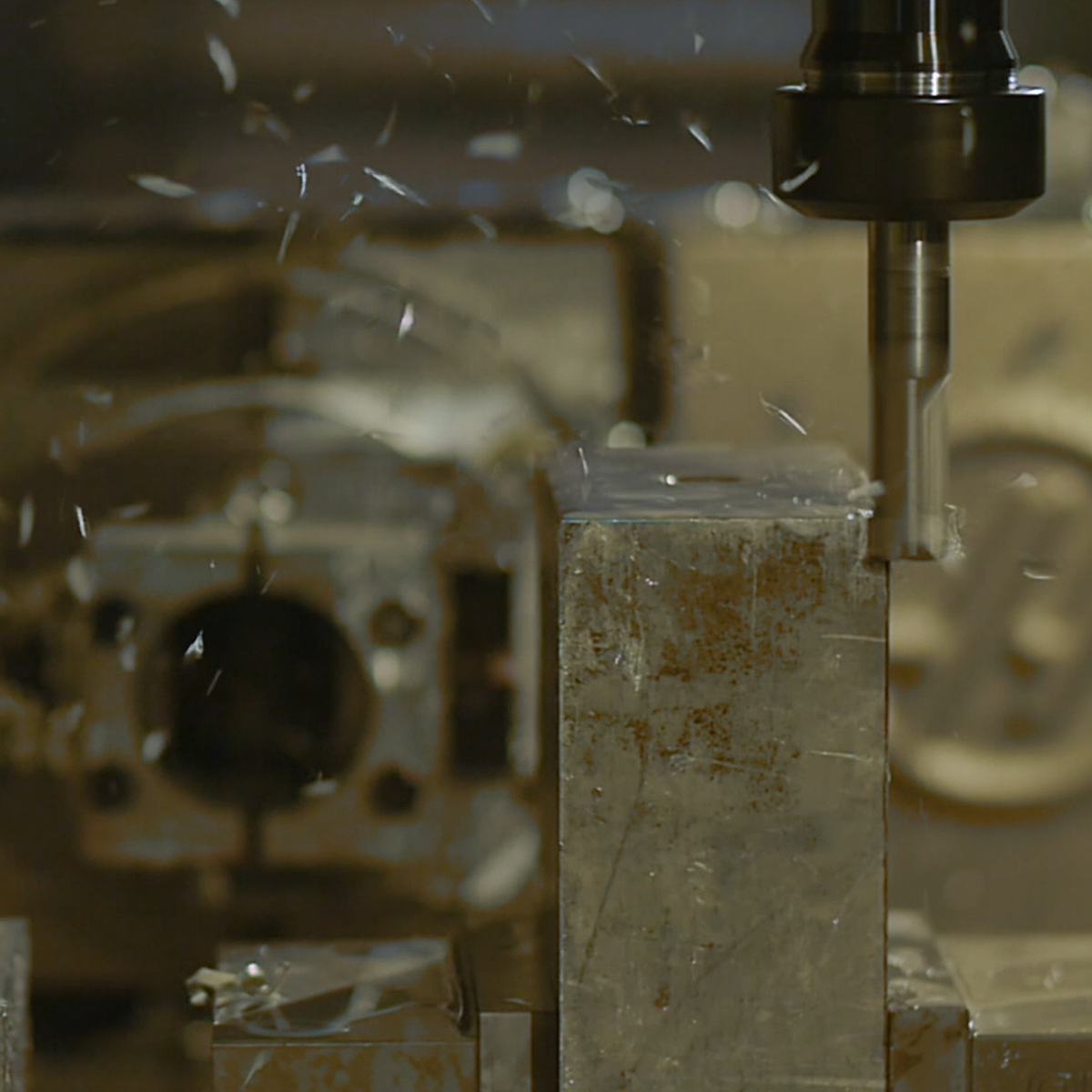

Introduction to Mechanical Engineering Design and Manufacturing with Fusion 360

Design for manufacturing is the process of designing parts, components, or products with the understanding surrounding design requirements for a specific manufacturing method.

This course explores the design for manufacture workflow and shows how to validate models and create the G code, the programming language needed to instruct the CNC machine on how to move. We practice the basics of part and assembly design, and tools such as animation, rendering, and simulations using Autodesk Fusion 360. We learn the basics in each of these areas which are to be fully developed in later courses that apply these principles and Fusion 360 skills.

After taking this course, you'll be able to:

- Explain the design to manufacturing process used to take a digital model to a physical part through CNC programming.

- Summarize the toolset available in Fusion 360.

- Demonstrate knowledge and skills in Fusion 360 applying design and manufacturing workflows to take digital parts to physical prototypes.

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

BIM Application for Engineers

In order to effectively reach the goal of learning, students will get familiar with the model-building process. The second module of the course will be on how to use Autodesk Revit to build BIM models. We will use an example case and guide students to build a 6-story BIM model from the CAD drawings step by step.

Then, in the following three modules, we will introduce three essential BIM applications one by one in each module, namely clash detection, quantity takeoff, and 4D simulation. We will use Autodesk Revit and Navisworks to build our BIM models in this course.

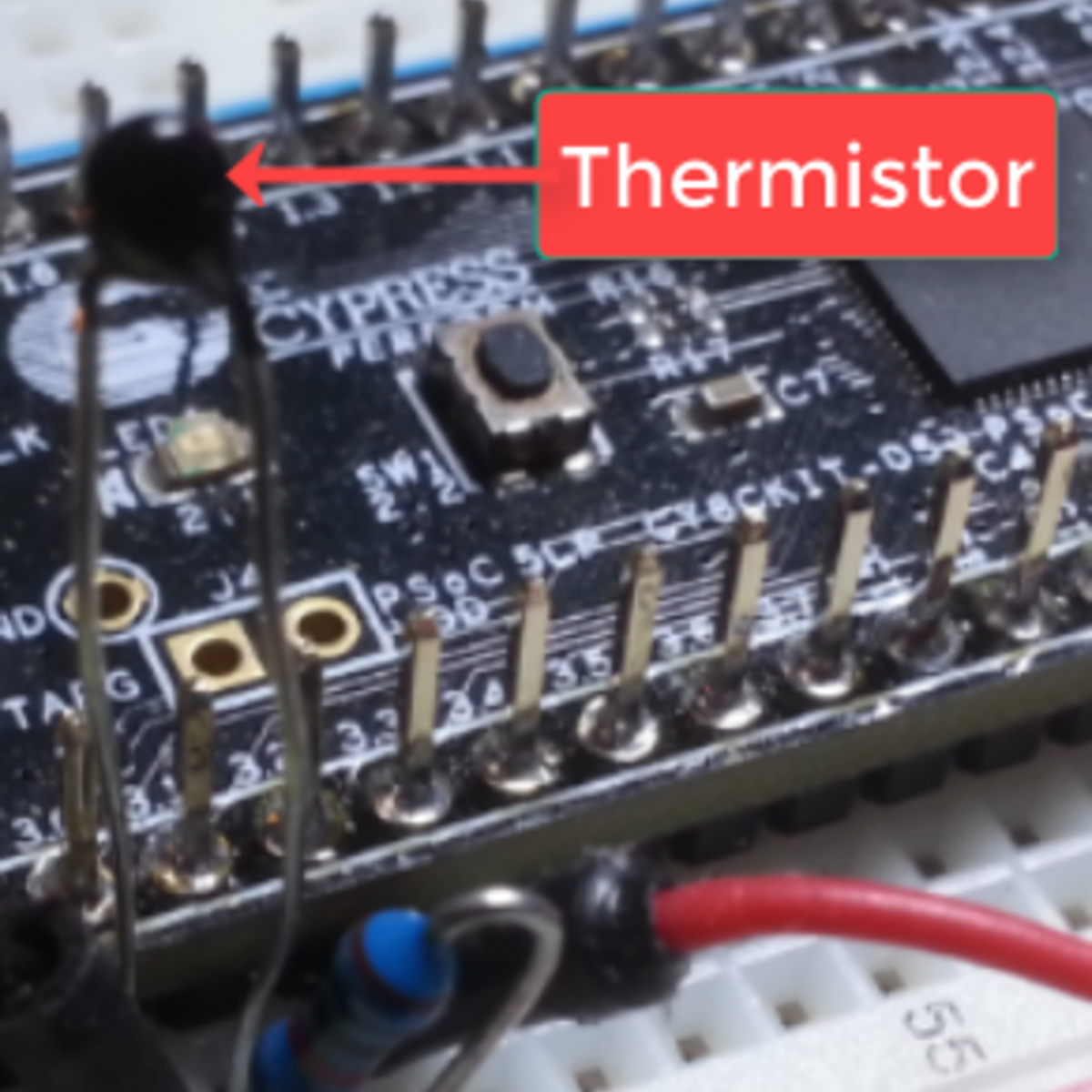

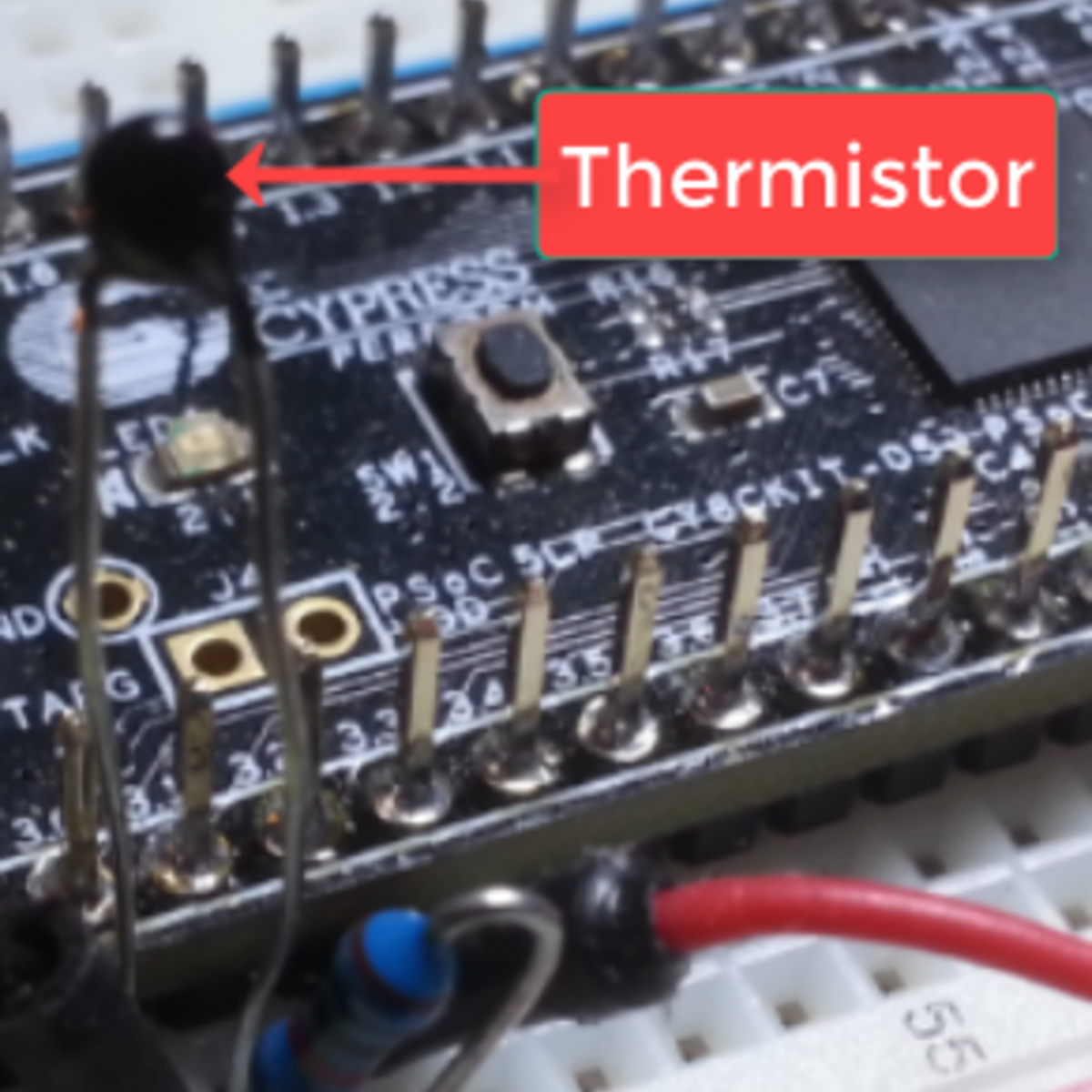

Sensors and Sensor Circuit Design

This course can also be taken for academic credit as ECEA 5340, part of CU Boulder’s Master of Science in Electrical Engineering degree.

After taking this course, you will be able to:

● Understand how to specify the proper thermal, flow, or rotary sensor for taking real-time process data.

● Implement thermal sensors into an embedded system in both hardware and software.

● Add the sensor and sensor interface into a microprocessor based development kit.

● Create hardware and firmware to process sensor signals and feed data to a microprocessor for further evaluation.

● Study sensor signal noise and apply proper hardware techniques to reduce it to acceptable levels.

You will need to buy the following components to do the two course projects based on the videos in this module. Note that if you have already purchased the PSOC 5LP PROTOTYPING KIT, you do not need to buy it again.

These parts may be purchased off the Digikey web site, www. Digikey.com. Or, you may obtain the specs from the site, and purchase them elsewhere.

These are the part numbers typed out, so you can copy and paste them into the Digikey web site. You will need one of each part.

428-3390-ND

NHD-0216BZ-RN-YBW-ND

570-1229-ND

A105970CT-ND

Additional equipment needed:

• Wire - various gauges and lengths

• Breadboard

• Oscilloscope – suggested models are:

o PICOSCOPE 2204A-D2 available on www.digikey.com or

o Digilent 410-324 | OpenScope MZ available on www.newark.com

Depending on your budget, you can also investigate these models:

o Hantek HT6022BE20MHz - https://www.amazon.com/dp/B009H4AYII

o SainSmart DSO212 - https://www.amazon.com/dp/B074QBQNB7

o PoScope Mega50 USB - https://www.robotshop.com/en/poscope-mega50-usb-mso-oscilloscope.html

o ADALM2000 - https://www.digikey.com/en/products/detail/analog-devices-inc./ADALM2000/7019661

Advanced Manufacturing Enterprise

Enterprises that seek to become proficient in advanced manufacturing must incorporate manufacturing management tools and integrate data throughout the supply chain to be successful. This course will make students aware of what a digitally connected enterprise is, as they learn about the operational complexity of enterprises, business process optimization and the concept of an integrated product-process-value chain.

Students will become acquainted with the available tools, technologies and techniques for aggregation and integration of data throughout the manufacturing supply chain and entire product life-cycle. They will receive foundational knowledge to assist in efforts to facilitate design, planning, and production scheduling of goods and services by applying product life cycle data.

Main concepts of this course will be delivered through lectures, readings, discussions and various videos.

This is the sixth course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturing’s “Fourth Revolution,” aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal. To learn more about the Digital Manufacturing and Design Technology specialization, please watch the overview video by copying and pasting the following link into your web browser: https://youtu.be/wETK1O9c-CA

Mechanics of Materials II: Thin-Walled Pressure Vessels and Torsion

This course explores the analysis and design of thin-walled pressure vessels and engineering structures subjected to torsion.

------------------------------------------------

The copyright of all content and materials in this course are owned by either the Georgia Tech Research Corporation or Dr. Wayne Whiteman. By participating in the course or using the content or materials, whether in whole or in part, you agree that you may download and use any content and/or material in this course for your own personal, non-commercial use only in a manner consistent with a student of any academic course. Any other use of the content and materials, including use by other academic universities or entities, is prohibited without express written permission of the Georgia Tech Research Corporation. Interested parties may contact Dr. Wayne Whiteman directly for information regarding the procedure to obtain a non-exclusive license.

Modern Robotics, Course 3: Robot Dynamics

Do you want to know how robots work? Are you interested in robotics as a career? Are you willing to invest the effort to learn fundamental mathematical modeling techniques that are used in all subfields of robotics?

If so, then the "Modern Robotics: Mechanics, Planning, and Control" specialization may be for you. This specialization, consisting of six short courses, is serious preparation for serious students who hope to work in the field of robotics or to undertake advanced study. It is not a sampler.

In Course 3 of the specialization, Robot Dynamics, you will learn efficient numerical algorithms for forward dynamics (calculating the robot's acceleration given its configuration, velocity, and joint forces and torques) and inverse dynamics (calculating the required joint forces and torques given the robot's configuration, velocity, and acceleration). The former is useful for simulation, and the latter is useful for robot control. You will also learn how to plan robot trajectories subject to dynamic constraints.

This course follows the textbook "Modern Robotics: Mechanics, Planning, and Control" (Lynch and Park, Cambridge University Press 2017). You can purchase the book or use the free preprint pdf. You will build on a library of robotics software in the language of your choice (among Python, Mathematica, and MATLAB) and use the free cross-platform robot simulator V-REP, which allows you to work with state-of-the-art robots in the comfort of your own home and with zero financial investment.

Digitalisation in Space Research

This course provides an overview of the most important digital applications in the field of aerospace research. The course instructors discuss how digitalisation is impacting and changing both satellite-based and manned spaceflight research. One unit is specifically devoted to exploring the use of artificial intelligence in the evaluation of satellite data.

Multi-Axis CNC Toolpaths

Computer Numerical Controlled machines, or CNC for short, can have a nearly endless number of options. Most machines today control tool motion in 3-axes, X, Y and Z, but can be upgraded to include a 4th or 5th axis as well, A and B. Additionally, there are many machines on the market that are already 5-axis capable. The good news is that Autodesk® Fusion 360™ has you covered if you need to control multi-axis positioning or simultaneous motion in all 5 axes at once!

Want to take your learning to the next level? Complete the Autodesk CAD/CAM for Manufacturing Specialization, and you’ll unlock an additional Autodesk Credential as further recognition of your success! The Autodesk Credential comes with a digital badge and certificate, which you can add to your resume and share on social media platforms like LinkedIn, Facebook, and Twitter. Sharing your Autodesk Credential can signal to hiring managers that you’ve got the right skills for the job and you’re up on the latest industry trends like generative design.

Enroll in the Specialization here: https://www.coursera.org/specializations/autodesk-cad-cam-manufacturing

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

Converter Circuits

This course can also be taken for academic credit as ECEA 5701, part of CU Boulder’s Master of Science in Electrical Engineering degree.

This course introduces more advanced concepts of switched-mode converter circuits. Realization of the power semiconductors in inverters or in converters having bidirectional power flow is explained. Power diodes, power MOSFETs, and IGBTs are explained, along with the origins of their switching times. Equivalent circuit models are refined to include the effects of switching loss. The discontinuous conduction mode is described and analyzed. A number of well-known converter circuit topologies are explored, including those with transformer isolation.

The homework assignments include a boost converter and an H-bridge inverter used in a grid-interfaced solar inverter system, as well as transformer-isolated forward and flyback converters.

After completing this course, you will:

● Understand how to implement the power semiconductor devices in a switching converter

● Understand the origins of the discontinuous conduction mode and be able to solve converters operating in DCM

● Understand the basic dc-dc converter and dc-ac inverter circuits

● Understand how to implement transformer isolation in a dc-dc converter, including the popular forward and flyback converter topologies

Completion of the first course Introduction to Power Electronics is the assumed prerequisite for this course.

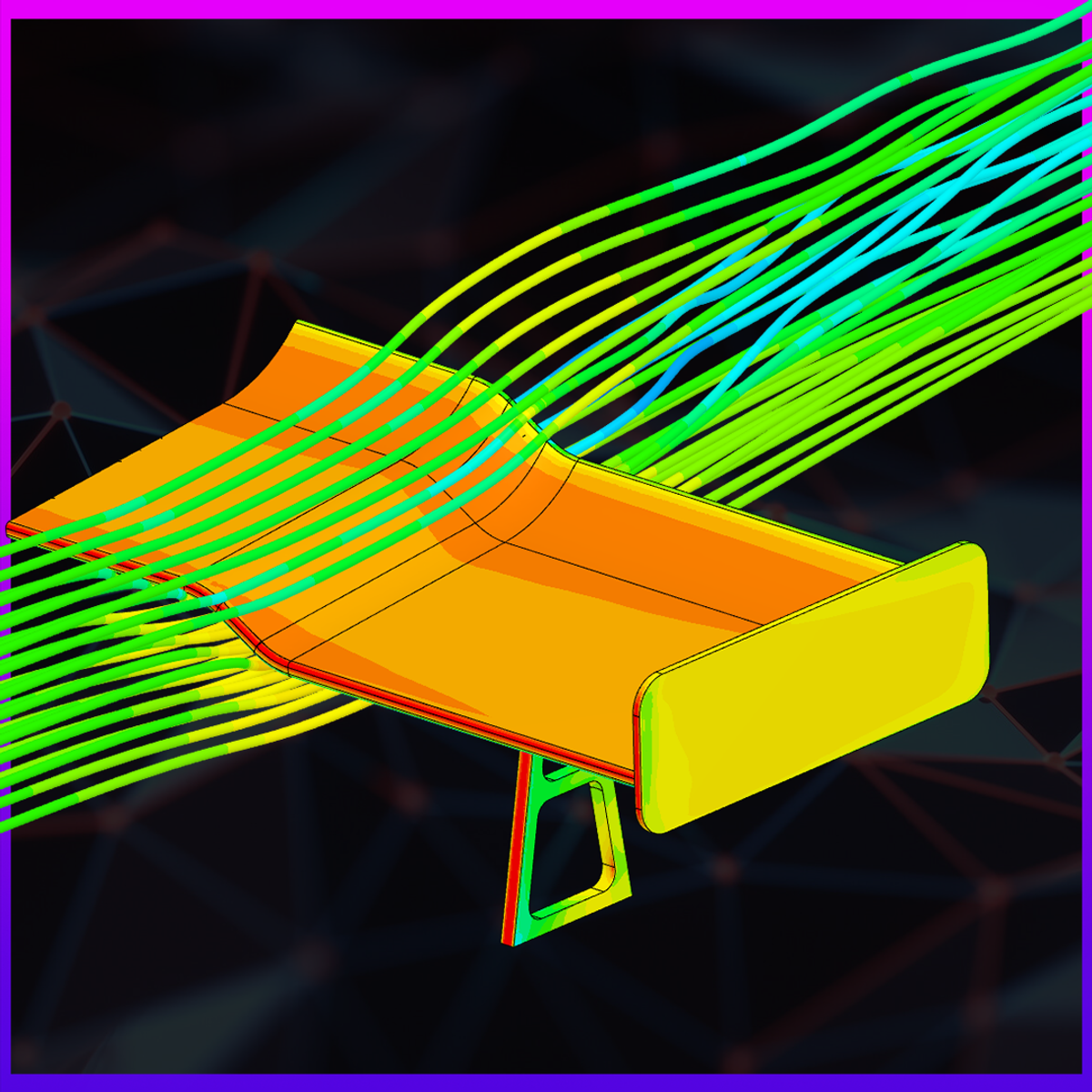

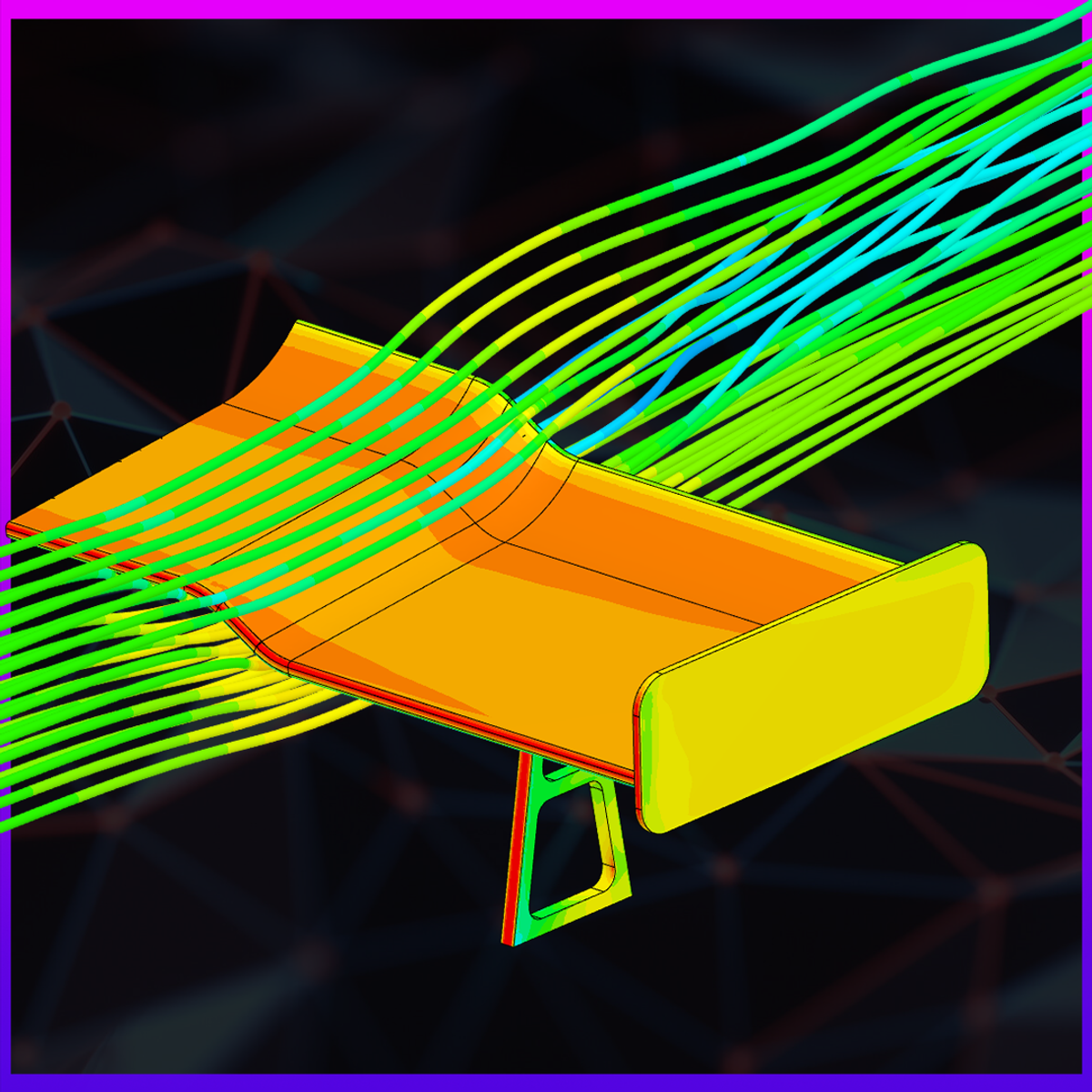

Computational Fluid Mechanics - Airflow Around a Spoiler

In this hands-on project, you will learn about Computational Fluid Dynamics (CFD) and perform an incompressible fluid flow simulation around a spoiler using the cloud-based simulation tool SimScale. We will set up simulation cases with provided geometries to learn the fundamentals of CFD and how a spoieler simulation is approached and set up in the first place. We will walk through the classical three step process of every simulation which includes the pre-processing, processing and post-processing step.

SimScale is an engineering simulation platform that is revolutionizing the way engineers, designers, scientists, and students design products. The SimScale platform is accessible completely via a standard web browser, with an easy-to-use interface which supports numerous simulation types including solid mechanics (FEM), fluid dynamics (CFD) & thermodynamics.

This course runs on Coursera's hands-on project platform called Rhyme. On Rhyme, you do projects in a hands-on manner in your browser. You will get instant access to pre-configured cloud desktops containing all of the software and data you need for the project, for this project you need no special setup or any data. Everything is already set up directly in your internet browser so you can just focus on learning!

Notes:

- This course works best for learners who are based in the North America region. We’re currently working on providing the same experience in other regions.

Popular Internships and Jobs by Categories

Find Jobs & Internships

Browse

© 2024 BoostGrad | All rights reserved