Back to Courses

Mechanical Engineering Courses - Page 10

Showing results 91-100 of 148

Electrical Properties and Semiconductors

In this course, we will explore the electrical properties of materials and classify different materials as conductors, semiconductors or insulators. We will look at some examples of conductors, semiconductors and insulators, and note the key factors that cause the differences in their electrical properties. We will use rudimentary band theory to show how temperature impacts the conductivity of the three classifications of materials. We will learn what causes the differences in electrical behavior of a p-type versus an n-type semiconductor in a p-n diode.

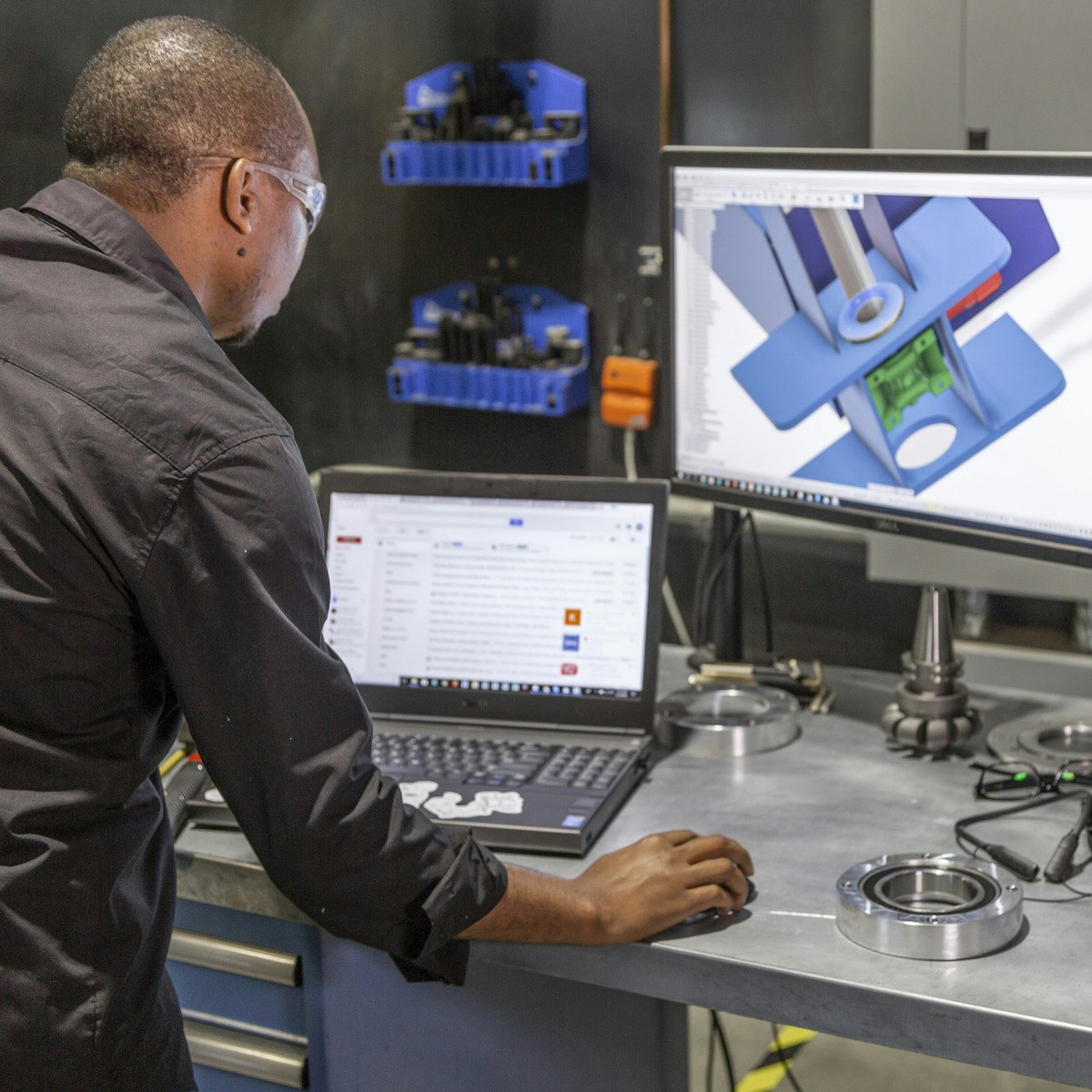

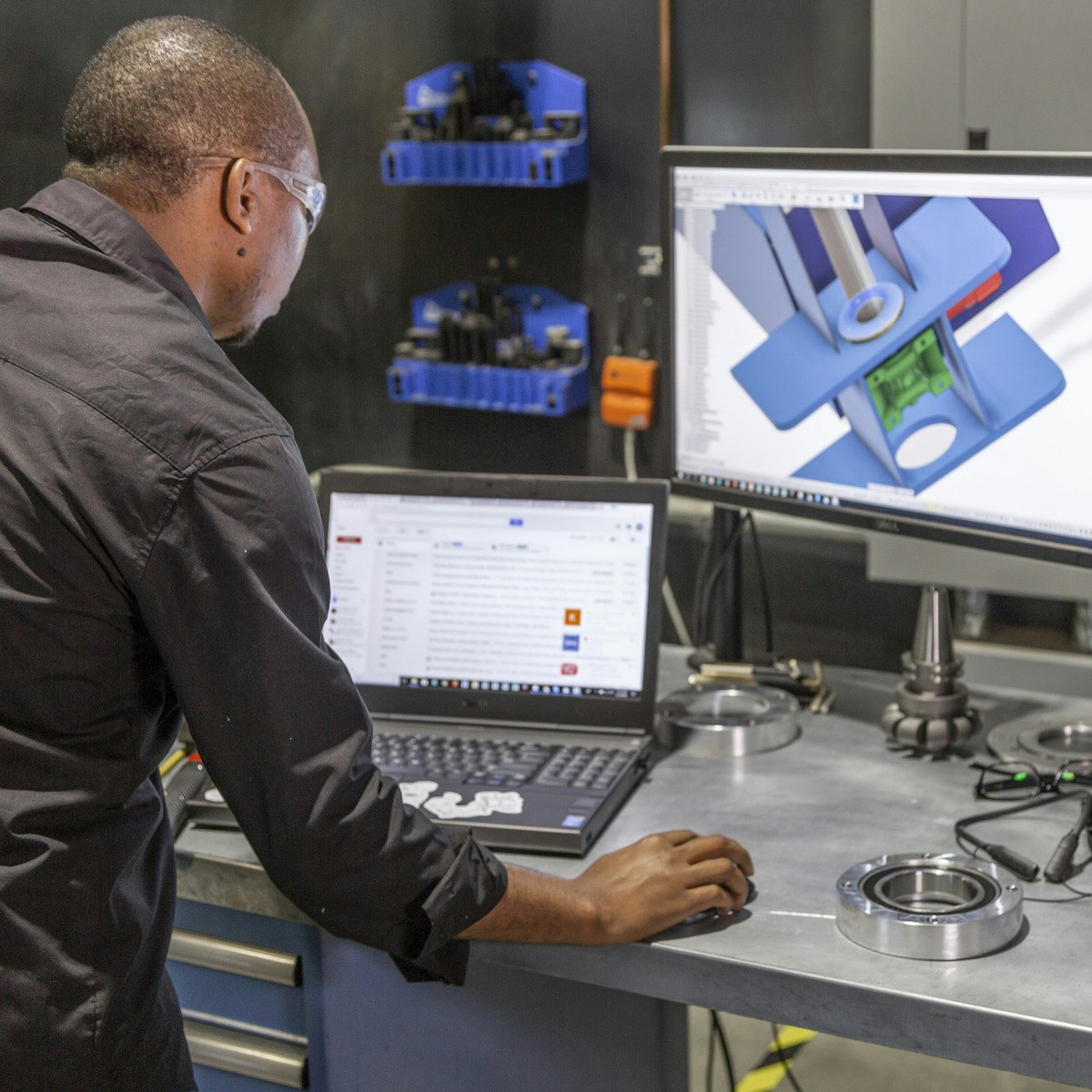

Cyber Security in Manufacturing

The nature of digital manufacturing and design (DM&D), and its heavy reliance on creating a digital thread of product and process data and information, makes it a prime target for hackers and counterfeiters. This course will introduce students to why creating a strong and secure infrastructure should be of paramount concern for anyone operating in the DM&D domain, and measures that can be employed to protect operational technologies, systems and resources.

Acquire knowledge about security needs and the application of information security systems. Build the foundational skills needed in performing a risk assessment of operational and information technology assets. Gain valuable insights of implementing controls to mitigate identified risks.

Main concepts of this course will be delivered through lectures, readings, discussions and various videos.

This is the seventh course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturing’s “Fourth Revolution,” aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal. To learn more about the Digital Manufacturing and Design Technology specialization, please watch the overview video by copying and pasting the following link into your web browser: https://youtu.be/wETK1O9c-CA

Autodesk Fusion 360 Integrated CAD/CAM/CAE

Design, engineering, and manufacturing are undergoing a digital transformation, and the need for a collaborative product development environment is becoming an ever-growing requirement. Autodesk® Fusion 360™ meets this need by connecting CAD, CAM, and CAE in a single cloud-based platform unlike any other tool of its kind. This course builds upon digital manufacturing trends and foundational CAD concepts discussed in Course 1 of this series by introducing Fusion 360 as a problem-solving tool. In this course, we take the next step in connecting CAD, CAM, and CAE through a series of short exercises on 3D modeling, rendering, simulation, and computer aided manufacturing.

After completing this course series, you will be able to:

• Demonstrate knowledge of and apply job entry level skills in computer aided design, computer aided engineering (CAE) and computer aided manufacturing (CAM) using Fusion 360 software.

• Describe and apply design based workflows for design, engineering and manufacturing using Fusion 360 software.

• Utilize Fusion 360 cloud based collaboration features for project sharing and design review.

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

Modeling and Design for Mechanical Engineers with Autodesk Fusion 360

There are many considerations that play a part in engineering a new product. Regardless of what that product is, there are fundamentals such as form, fit, and function when it comes to digital modeling. In this course, we lay the foundation to create any design and dive deep into topics about the control of the design. From assembly joints and joint limits to complex shapes using forms, rest assured that your design will be rock solid.

After completing this course you'll be able to:

- Create and drive a mechanical gear assembly.

- Create and modify a form-based design.

- Use design tools for molded parts.

- Demonstrate proficiency in the setup and creation of a design.

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

Creating Toolpaths for a CNC Lathe

CNC machines come in an almost endless array of configurations for various applications. So far, we have only talked about CNC Mills. More specifically vertical milling centers. In this course we turn our attention to the CNC Lathe. We identify the difference in a lathe’s coordinate system, tools, and how to create lathe specific toolpaths.

Want to take your learning to the next level? Complete the Autodesk CAD/CAM for Manufacturing Specialization, and you’ll unlock an additional Autodesk Credential as further recognition of your success! The Autodesk Credential comes with a digital badge and certificate, which you can add to your resume and share on social media platforms like LinkedIn, Facebook, and Twitter. Sharing your Autodesk Credential can signal to hiring managers that you’ve got the right skills for the job and you’re up on the latest industry trends like generative design.

Enroll in the Specialization here: https://www.coursera.org/specializations/autodesk-cad-cam-manufacturing

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

Generative Design for Performance and Weight Reduction

There are many considerations and factors that play a part in designing a new product. Cost is usually a big one, but sometimes there are other factors that are the main contributors to a product's direction. With vehicles, specifically motorcycles, we see advanced engineering practices performed on seemingly minor parts. In some instances, making a part as light as possible can have a big effect on performance. In other cases, the strength or stiffness of a part, such as a motor mount, is more critical than its mass. Generative design allows us the ability to solve for both problems at the same time and make informed design decisions without the sacrifice. In this course, we’ll explore how generative design can be applied to motorcycle parts to help reduce mass while also increasing performance.

You’ll need a paid subscription to Fusion 360 to complete the assignments in this course. Be sure to review your access or payment options before enrolling: https://www.autodesk.com/products/fusion-360

Want to take your learning to the next level? Complete the Autodesk Generative Design for Manufacturing Specialization, and you’ll unlock an additional Autodesk Credential as further recognition of your success! The Autodesk Credential comes with a digital badge and certificate, which you can add to your resume and share on social media platforms like LinkedIn, Facebook, and Twitter. Sharing your Autodesk Credential can signal to hiring managers that you’ve got the right skills for the job and you’re up on the latest industry trends like generative design.

Enroll in the Specialization here: https://www.coursera.org/specializations/autodesk-generative-design-manufacturing

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

Techniques of Design-Oriented Analysis

This course can also be taken for academic credit as ECEA 5706, part of CU Boulder’s Master of Science in Electrical Engineering degree.

This is Course #2 in the Modeling and Control of Power Electronics course sequence. The course is focused on techniques of design-oriented analysis that allow you to quickly gain insights into models of switching power converters and to translate these insights into practical converter designs. The design-oriented techniques covered are the Extra Element Theorem and the N-Extra Element Theorem (N-EET). Through practical examples, it is shown how the EET can be used to simplify circuit analysis, to examine the effects of initially unmodeled components, and to design damping of converters such as SEPIC and Cuk to achieve high-performance closed-loop controls. The N-EET will allow you to perform circuit analysis and to derive circuit responses with minimum algebra. Modeling and design examples are supported by design-oriented MATLAB script and Spice simulations. After completion of this course, the student will gain analytical skills applicable to the design of high-performance closed-loop controlled switching power converters.

We strongly recommend students complete the CU Boulder Power Electronics specialization as well as Course #1 Averaged-Switch Modeling and Simulation before enrolling in this course (the course numbers provided below are for students in the CU Boulder's MS-EE program):

● Introduction to Power Electronics (ECEA 5700)

● Converter Circuits (ECEA 5701)

● Converter Control (ECEA 5702)

● Averaged-Switch Modeling and Simulation (ECEA 5705)

After completing this course, you will be able to:

● Understand statement and derivation of the Extra Element Theorem

● Apply the Extra Element Theorem to converter analysis and design problems

● Understand the statement of the N-Extra Element Theorem

● Apply the N-Extra Element Theorem to converter analysis and design problems

● Apply techniques of design-oriented analysis to analysis, design, and simulations of switching converters

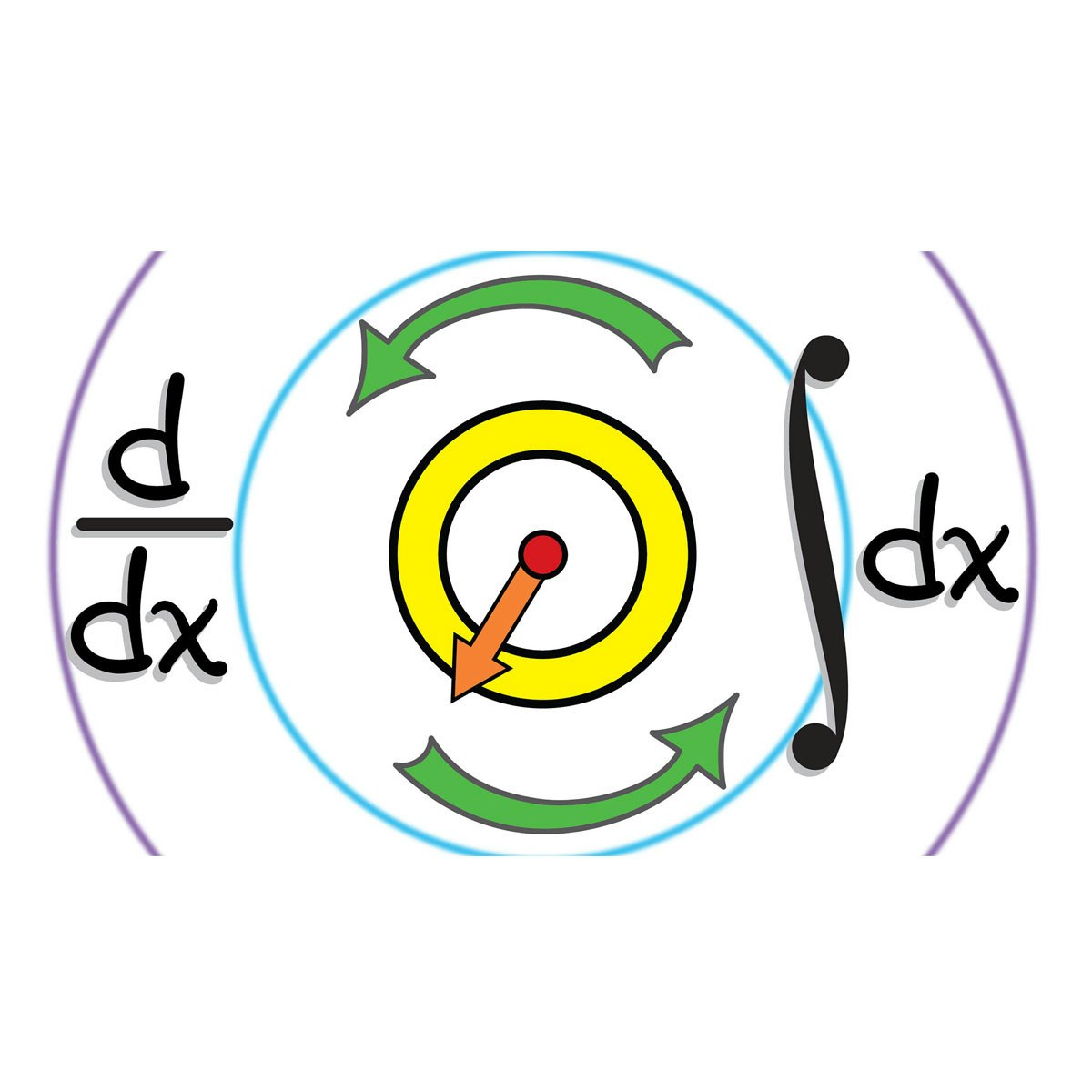

Calculus: Single Variable Part 3 - Integration

Calculus is one of the grandest achievements of human thought, explaining everything from planetary orbits to the optimal size of a city to the periodicity of a heartbeat. This brisk course covers the core ideas of single-variable Calculus with emphases on conceptual understanding and applications. The course is ideal for students beginning in the engineering, physical, and social sciences. Distinguishing features of the course include: 1) the introduction and use of Taylor series and approximations from the beginning; 2) a novel synthesis of discrete and continuous forms of Calculus; 3) an emphasis on the conceptual over the computational; and 4) a clear, dynamic, unified approach.

In this third part--part three of five--we cover integrating differential equations, techniques of integration, the fundamental theorem of integral calculus, and difficult integrals.

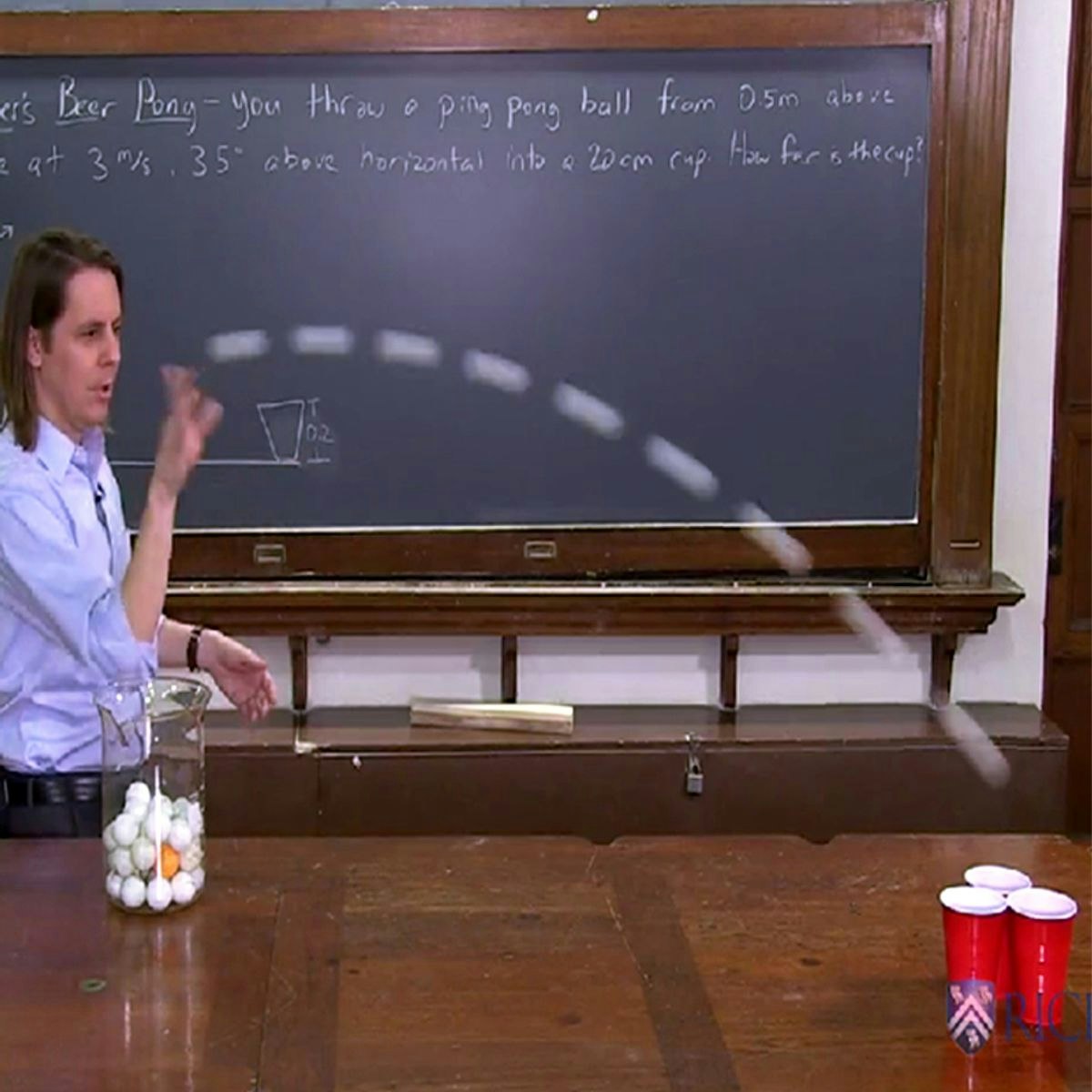

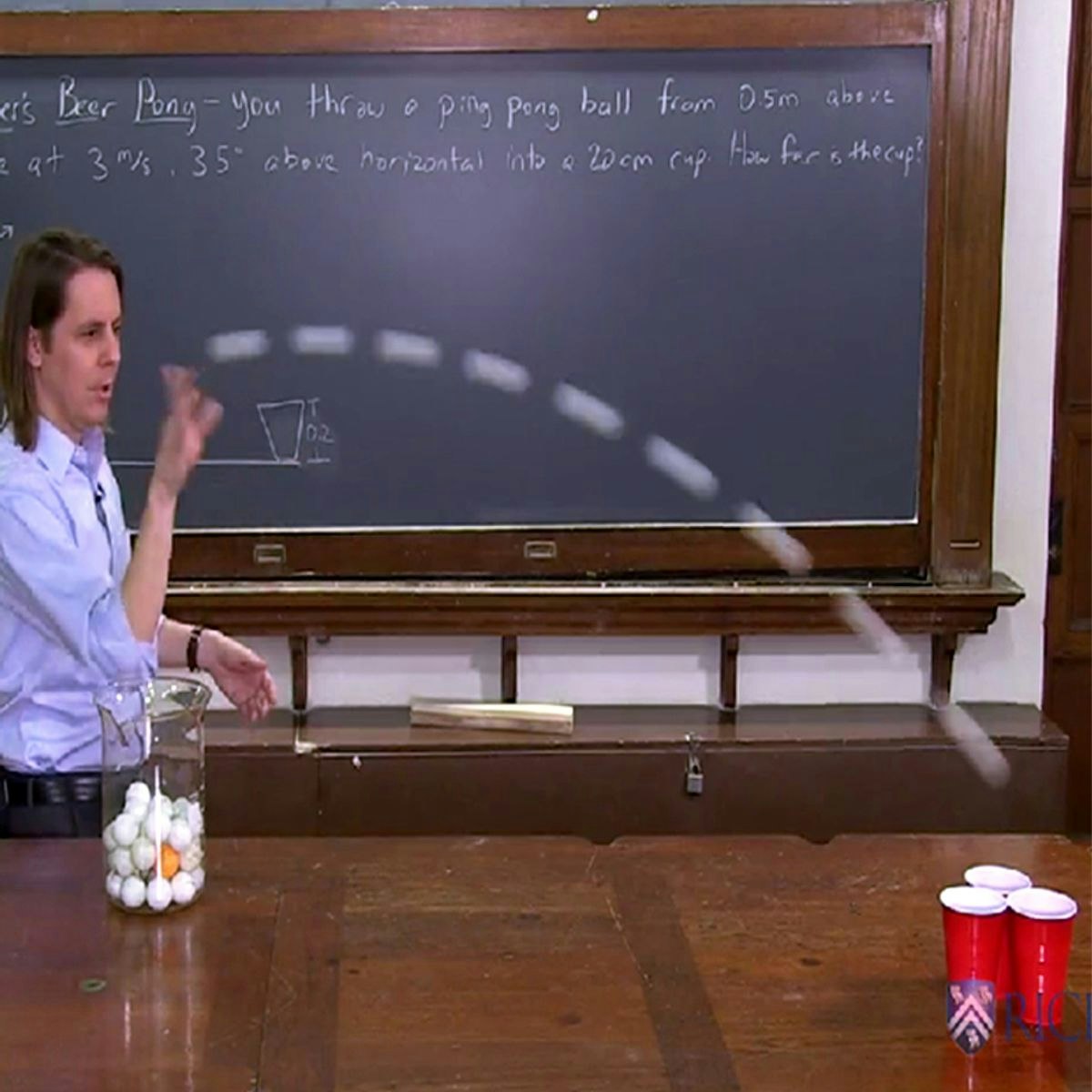

Physics 101 - Forces and Kinematics

This course serves as an introduction to the physics of force and motion. Upon completion, learners will have an understanding of how mathematical laws and conservation principles describe the motions and interactions of objects all around us. They will gain experience in solving physics problems with tools such as graphical analysis, algebra, vector analysis, and calculus. The course follows the typical progression of topics of a first-semester university physics course: Kinematics, Newton’s Laws, Energy, and Momentum. Each of five modules contains reading links to a free textbook, complete video lectures, conceptual quizzes, and a set of homework problems. Once the modules are completed, the course ends with an exam. With 100 brief lectures and over 100 problems, this comprehensive course is similar in detail and rigor to those taught on-campus. It will thoroughly prepare learners for their upcoming introductory physics courses, or more advanced courses in physics.

CAM and Design Manufacturing for Mechanical Engineers with Autodesk Fusion 360

With design for manufacturing, our design process focused on the design over its cost, but always keeping in mind how parts needed to be made. With manufacturing at the core of a design, we're able to fix potential problems in the design phase rather than after production. In many cases, the end product is made up of an assembly of different pieces to simplify manufacturing or to achieve specific design goals. Each piece represents a certain tolerance and put together, things might not work or fit if they weren’t accounted for in the design.

We'll take a closer look at design and detail for manufacture and create toolpaths to cut parts. Even if the end goal as an engineer isn’t to fabricate your own parts, it’s a valuable skill to understand how things are made and what design decisions can ultimately affect how something is created.

After taking this course, you'll be able to:

- Inspect a multicomponent assembly.

- Identify manufacturing methods based on part inspection.

- Create detailed drawings for manufacturing.

- Practice creating toolpaths for manufacture.

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

Popular Internships and Jobs by Categories

Find Jobs & Internships

Browse

© 2024 BoostGrad | All rights reserved