Back to Courses

Mechanical Engineering Courses - Page 7

Showing results 61-70 of 148

Machine Design Part I

“Machine Design Part I” is the first course in an in-depth three course series of “Machine Design.” The “Machine Design” Coursera series covers fundamental mechanical design topics, such as static and fatigue failure theories, the analysis of shafts, fasteners, and gears, and the design of mechanical systems such as gearboxes. Throughout this series of courses we will examine a number of exciting design case studies, including the material selection of a total hip implant, the design and testing of the wing on the 777 aircraft, and the impact of dynamic loads on the design of an bolted pressure vessel.

In this first course, you will learn robust analysis techniques to predict and validate design performance and life. We will start by reviewing critical material properties in design, such as stress, strength, and the coefficient of thermal expansion. We then transition into static failure theories such as von Mises theory, which can be utilized to prevent failure in static loading applications such as the beams in bridges. Finally, we will learn fatigue failure criteria for designs with dynamic loads, such as the input shaft in the transmission of a car.

Mechanics of Materials IV: Deflections, Buckling, Combined Loading & Failure Theories

This course explores the analysis and design of engineering structures considering factors of deflection, buckling, combined loading, & failure theories

-------------------------------------------------

The copyright of all content and materials in this course are owned by either the Georgia Tech Research Corporation or Dr. Wayne Whiteman. By participating in the course or using the content or materials, whether in whole or in part, you agree that you may download and use any content and/or material in this course for your own personal, non-commercial use only in a manner consistent with a student of any academic course. Any other use of the content and materials, including use by other academic universities or entities, is prohibited without express written permission of the Georgia Tech Research Corporation. Interested parties may contact Dr. Wayne Whiteman directly for information regarding the procedure to obtain a non-exclusive license.

MBSE: Model-Based Systems Engineering

This Model-Based Systems Engineering (MBSE) course and the Digital Thread courses featured earlier in this specialization bring together the concepts from across digital manufacturing and design, forming a vision in which the geometry of a product is just one way of describing it. MBSE is where the model resulting from the evolution of system requirements, design, analysis, verification and validation activities is the focus of design and manufacturing. Students will gain an understanding of systems engineering, the model-based approach to design and manufacturing, the Digital Twin, and a roadmap toward a model-based enterprise.

Students will be able to explain the value and expectations of systems engineering and model-based systems engineering, and the underlying motivations and opportunities represented by a model-based enterprise. They will develop the knowledge necessary to perform a baseline assessment of an organization’s potential to leverage MBSE.

Main concepts of this course will be delivered through lectures, readings, discussions and various videos.

This is the eighth course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturing’s “Fourth Revolution,” aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal. To learn more about the Digital Manufacturing and Design Technology specialization, please watch the overview video by copying and pasting the following link into your web browser: https://youtu.be/wETK1O9c-CA

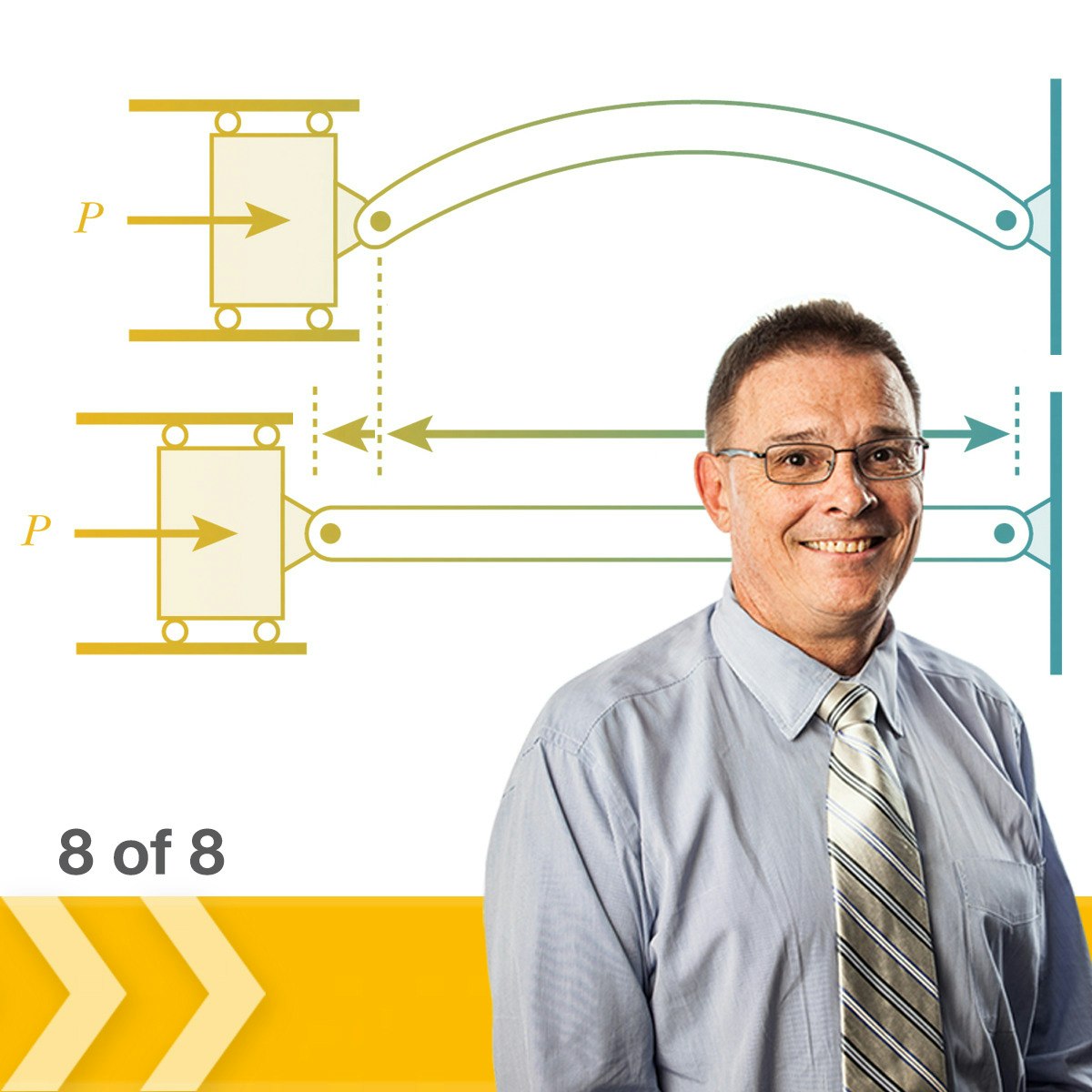

Averaged-Switch Modeling and Simulation

This course can also be taken for academic credit as ECEA 5705, part of CU Boulder’s Master of Science in Electrical Engineering degree.

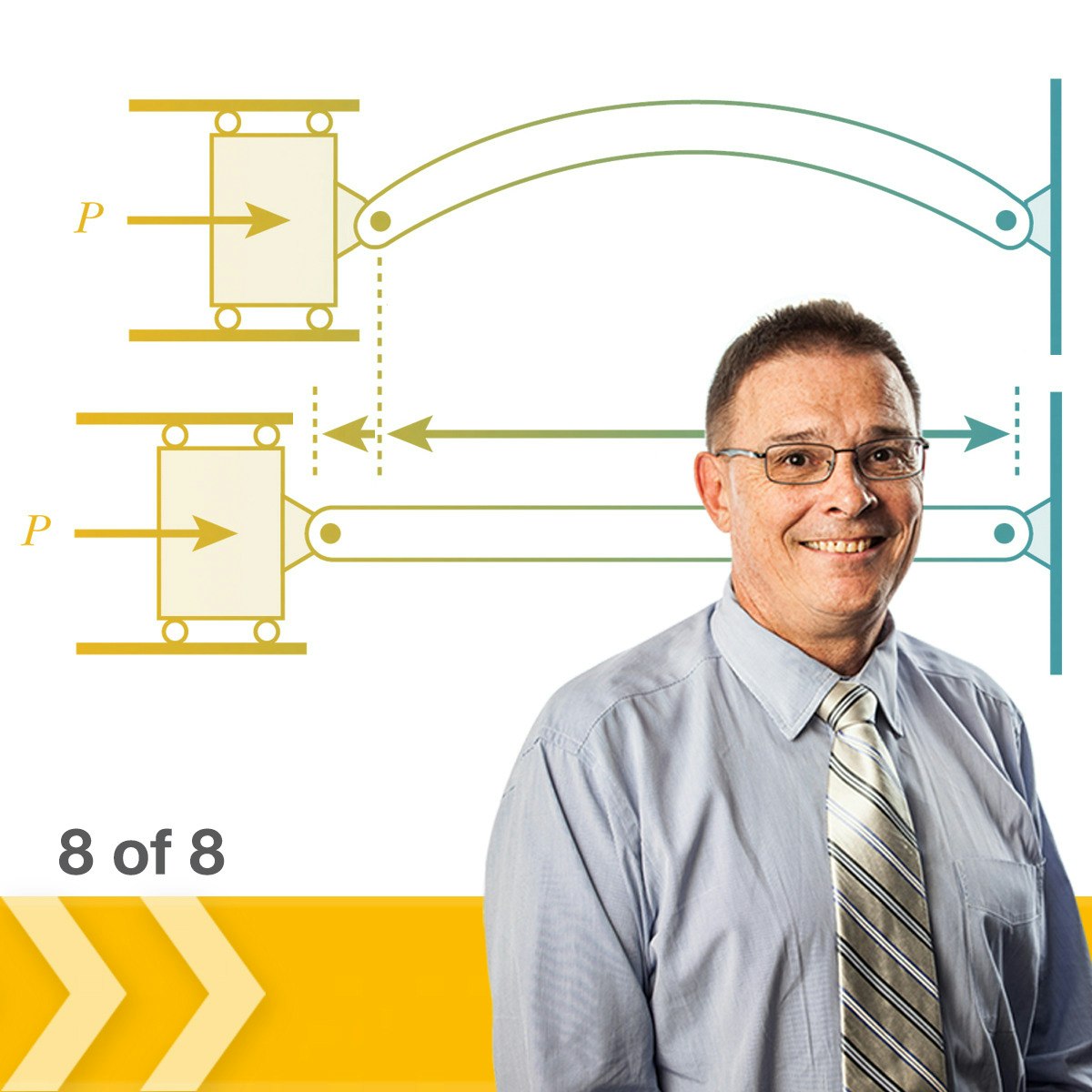

This is Course #1 in the Modeling and Control of Power Electronics course sequence. The course is focused on practical design-oriented modeling and control of pulse-width modulated switched mode power converters using analytical and simulation tools in time and frequency domains. A design-oriented analysis technique known as the Middlebrook's feedback theorem is introduced and applied to analysis and design of voltage regulators and other feedback circuits. Furthermore, it is shown how circuit averaging and averaged-switch modeling techniques lead to converter averaged models suitable for hand analysis, computer-aided analysis, and simulations of converters. After completion of this course, the student will be able to practice design of high-performance control loops around switched-mode power converters using analytical and simulation techniques.

We strongly recommend students complete the CU Boulder Power Electronics specialization before enrolling in this course (course numbers provided for students in CU Boulder's MS-EE program):

● Introduction to Power Electronics (ECEA 5700)

● Converter Circuits (ECEA 5701)

● Converter Control (ECEA 5702)

After completing this course, you will be able to:

● Explain operation and modeling of switched-mode power converters

● Model open-loop transfer functions and frequency responses

● Design closed-loop regulated switched-mode power converters

● Verify operation of switched-mode power converters by simulations

● Understand the Feedback Theorem principles

● Apply the Feedback Theorem to practical design examples

● Derive averaged switch models of and averaged circuit models of power converters

● Apply averaged-switch modeling techniques to analysis and design and simulations of power converters

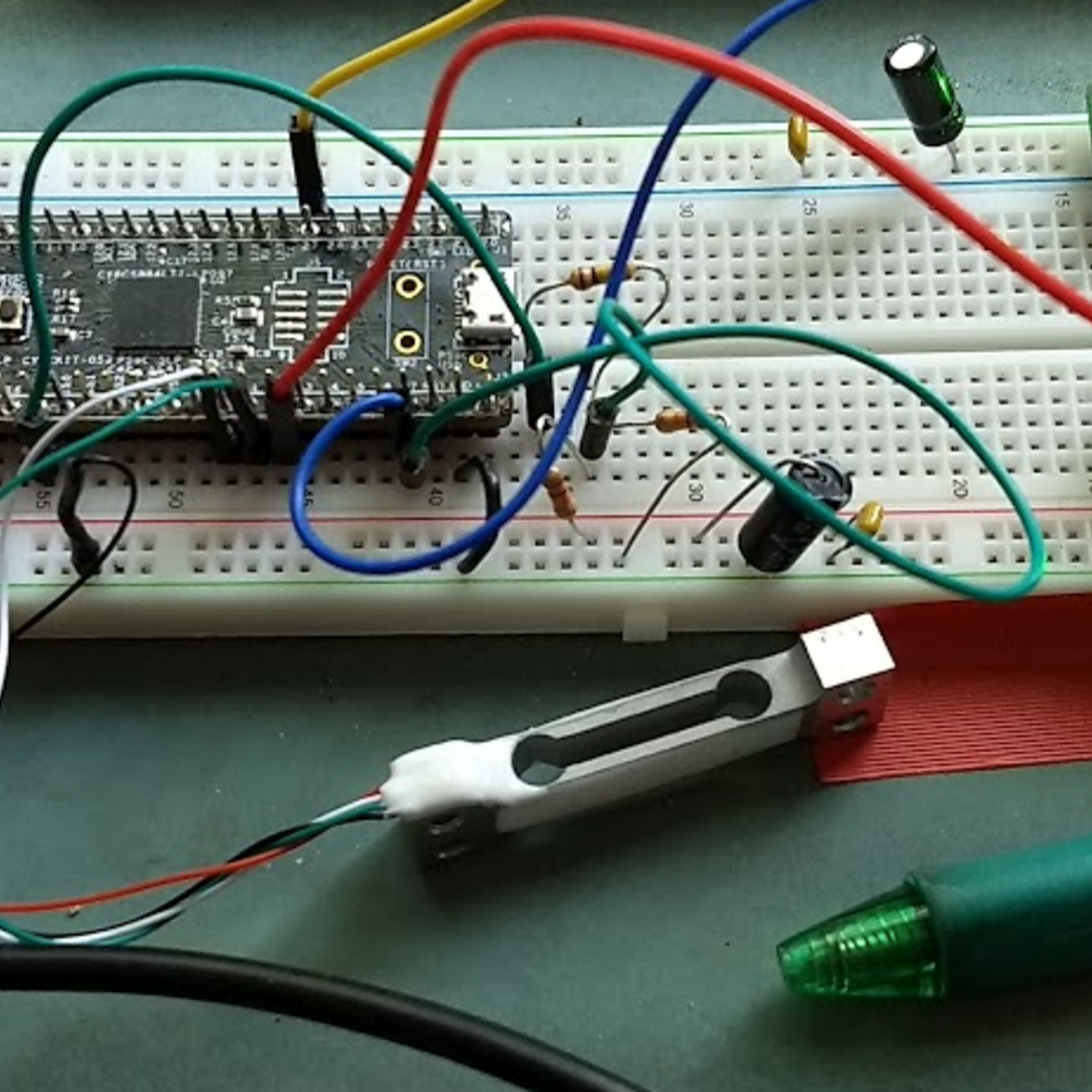

Pressure, Force, Motion, and Humidity Sensors

"Pressure, Force, Motion, and Humidity Sensors" can also be taken for academic credit as ECEA 5342, part of CU Boulder’s Master of Science in Electrical Engineering degree.

This is our third course in our specialization on Embedding Sensor and Motors. To get the most out of this course, you should first take our first course entitled Sensors and Sensor Circuits. Our first course gives you a tutorial on how to use the hardware and software development kit we have chosen for the lab exercises. This third course assumes that you already know how to use the kit.

After taking this course, you will be able to:

● Understand how to specify the proper AC or DC motor for a machine design.

● Integrate the motor to a machine, based on analysis of motor equations for voltage, current, torque and speed.

● Implement the motor and accompanying rotary sensor into a motor control circuit in both hardware and software.

● Add a motor and motor control circuit into a microprocessor based development kit.

● Create hardware and firmware to process motor feedback data to a microprocessor for further evaluation.

After taking this course, you will be able to:

● Understand how to specify the proper pressure, force, strain, position, motion, acceleration, occupancy, and humidity sensors for taking real-time process data.

● Implement these sensors into an embedded system in both hardware and software.

● Add the sensor and sensor interface into a microprocessor based development kit.

● Create hardware and firmware to process sensor signals and feed data to a microprocessor for further evaluation.

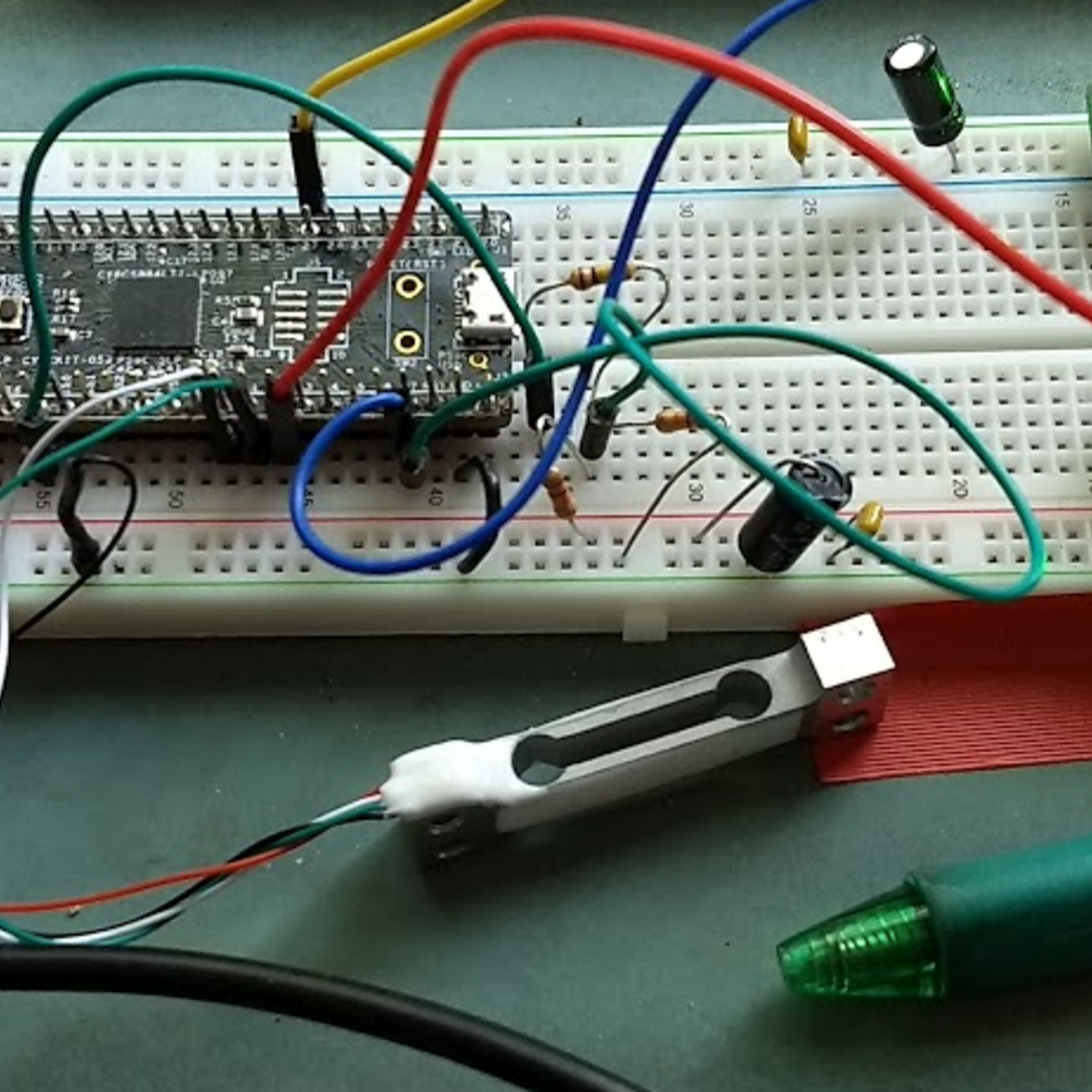

In this course you will build the circuit from Video 7 (Lab Exercise on strain gauges), Module 2 (Force and Strain Sensors and Touch Screens), and use it to make screen shots of the timing of the switch. If you haven't already wired up the system and written all the software per the instructions of Video 7, please do so now.

You will need to buy the following components to complete this assignment. Note that if you have already purchased the PSOC 5LP PROTOTYPING KIT, you do not need to buy it again.

These parts may be purchased off the Digikey web site, www. Digikey.com. One part needs to be purchased off the Sparkfun website www.sparkfun.com. Or, you may obtain the specs from the site, and purchase them elsewhere.

Digikey Part numbers are typed out here:

428-3390-ND

CF14JT22K0CT-ND

CF14JT100KCT-ND

Table shown here:

Index Quantity Part Number Description

1 1 428-3390-ND PSOC 5LP PROTOTYPING KIT

2 2 CF14JT22K0CT-ND RES 22K OHM 1/4W 5% AXIAL

3 1 CF14JT100KCT-ND RES 100K OHM 1/4W 5% AXIAL

Sparkfun part numbers are typed out here:

TAL221

Table shown here:

Index Quantity Part Number Description

1 1 TAL221 Mini-load cell - 100g, straight bar

Additional equipment needed:

• Wire - various gauges and lengths

• Breadboard

• Oscilloscope – suggested models are:

o PICOSCOPE 2204A-D2 available on www.digikey.com or

o Digilent 410-324 | OpenScope MZ available on www.newark.com

Depending on your budget, you can also investigate these models:

o Hantek HT6022BE20MHz - https://www.amazon.com/dp/B009H4AYII

o SainSmart DSO212 - https://www.amazon.com/dp/B074QBQNB7

o PoScope Mega50 USB - https://www.robotshop.com/en/poscope-mega50-usb-mso-oscilloscope.html

o ADALM2000 - https://www.digikey.com/en/products/detail/analog-devices-inc./ADALM2000/7019661

The Finite Element Method for Problems in Physics

This course is an introduction to the finite element method as applicable to a range of problems in physics and engineering sciences. The treatment is mathematical, but only for the purpose of clarifying the formulation. The emphasis is on coding up the formulations in a modern, open-source environment that can be expanded to other applications, subsequently.

The course includes about 45 hours of lectures covering the material I normally teach in an

introductory graduate class at University of Michigan. The treatment is mathematical, which is

natural for a topic whose roots lie deep in functional analysis and variational calculus. It is not

formal, however, because the main goal of these lectures is to turn the viewer into a

competent developer of finite element code. We do spend time in rudimentary functional

analysis, and variational calculus, but this is only to highlight the mathematical basis for the

methods, which in turn explains why they work so well. Much of the success of the Finite

Element Method as a computational framework lies in the rigor of its mathematical

foundation, and this needs to be appreciated, even if only in the elementary manner

presented here. A background in PDEs and, more importantly, linear algebra, is assumed,

although the viewer will find that we develop all the relevant ideas that are needed.

The development itself focuses on the classical forms of partial differential equations (PDEs):

elliptic, parabolic and hyperbolic. At each stage, however, we make numerous connections to

the physical phenomena represented by the PDEs. For clarity we begin with elliptic PDEs in

one dimension (linearized elasticity, steady state heat conduction and mass diffusion). We

then move on to three dimensional elliptic PDEs in scalar unknowns (heat conduction and

mass diffusion), before ending the treatment of elliptic PDEs with three dimensional problems

in vector unknowns (linearized elasticity). Parabolic PDEs in three dimensions come next

(unsteady heat conduction and mass diffusion), and the lectures end with hyperbolic PDEs in

three dimensions (linear elastodynamics). Interspersed among the lectures are responses to

questions that arose from a small group of graduate students and post-doctoral scholars who

followed the lectures live. At suitable points in the lectures, we interrupt the mathematical

development to lay out the code framework, which is entirely open source, and C++ based.

Books:

There are many books on finite element methods. This class does not have a required

textbook. However, we do recommend the following books for more detailed and broader

treatments than can be provided in any form of class:

The Finite Element Method: Linear Static and Dynamic Finite Element Analysis, T.J.R.

Hughes, Dover Publications, 2000.

The Finite Element Method: Its Basis and Fundamentals, O.C. Zienkiewicz, R.L. Taylor and

J.Z. Zhu, Butterworth-Heinemann, 2005.

A First Course in Finite Elements, J. Fish and T. Belytschko, Wiley, 2007.

Resources:

You can download the deal.ii library at dealii.org. The lectures include coding tutorials where

we list other resources that you can use if you are unable to install deal.ii on your own

computer. You will need cmake to run deal.ii. It is available at cmake.org.

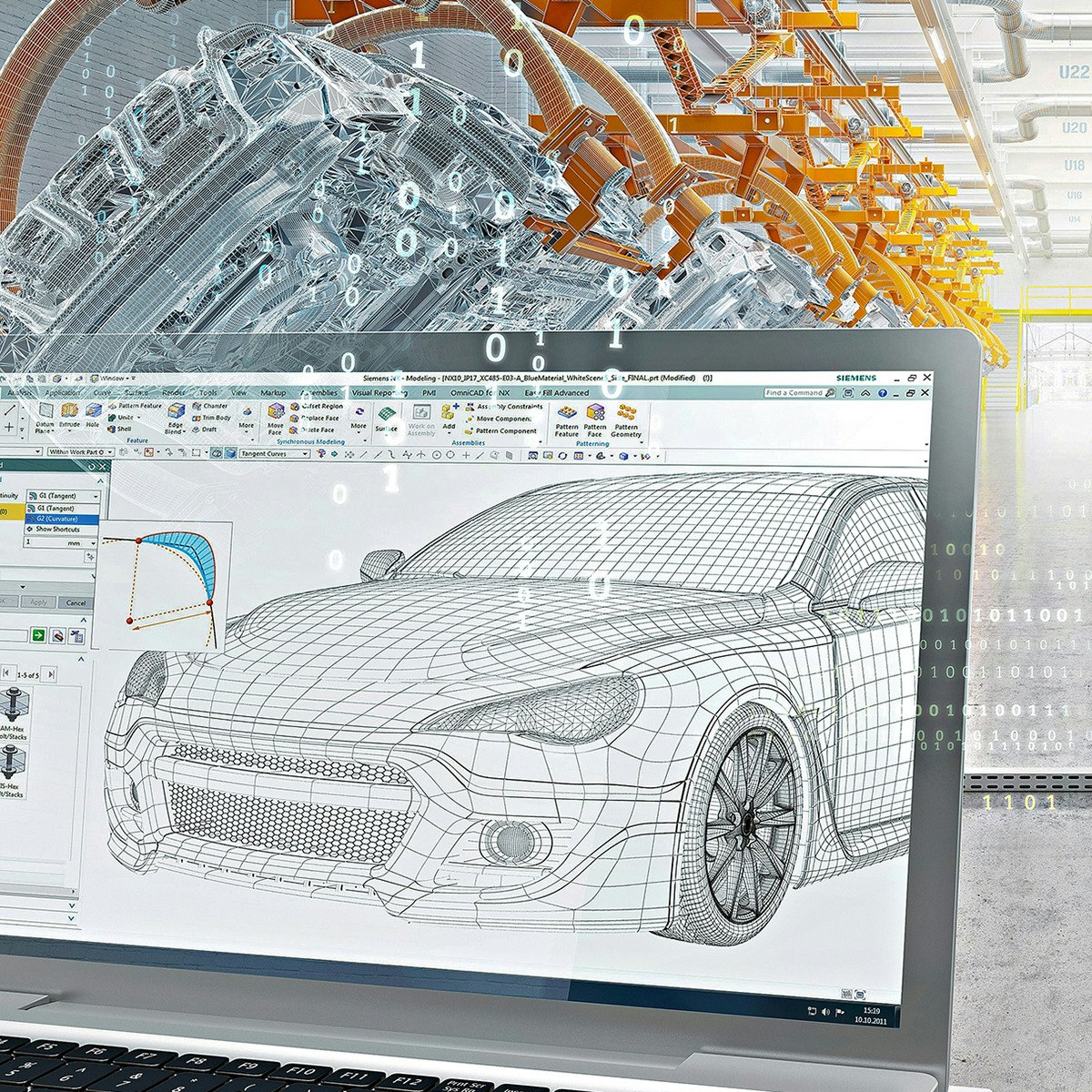

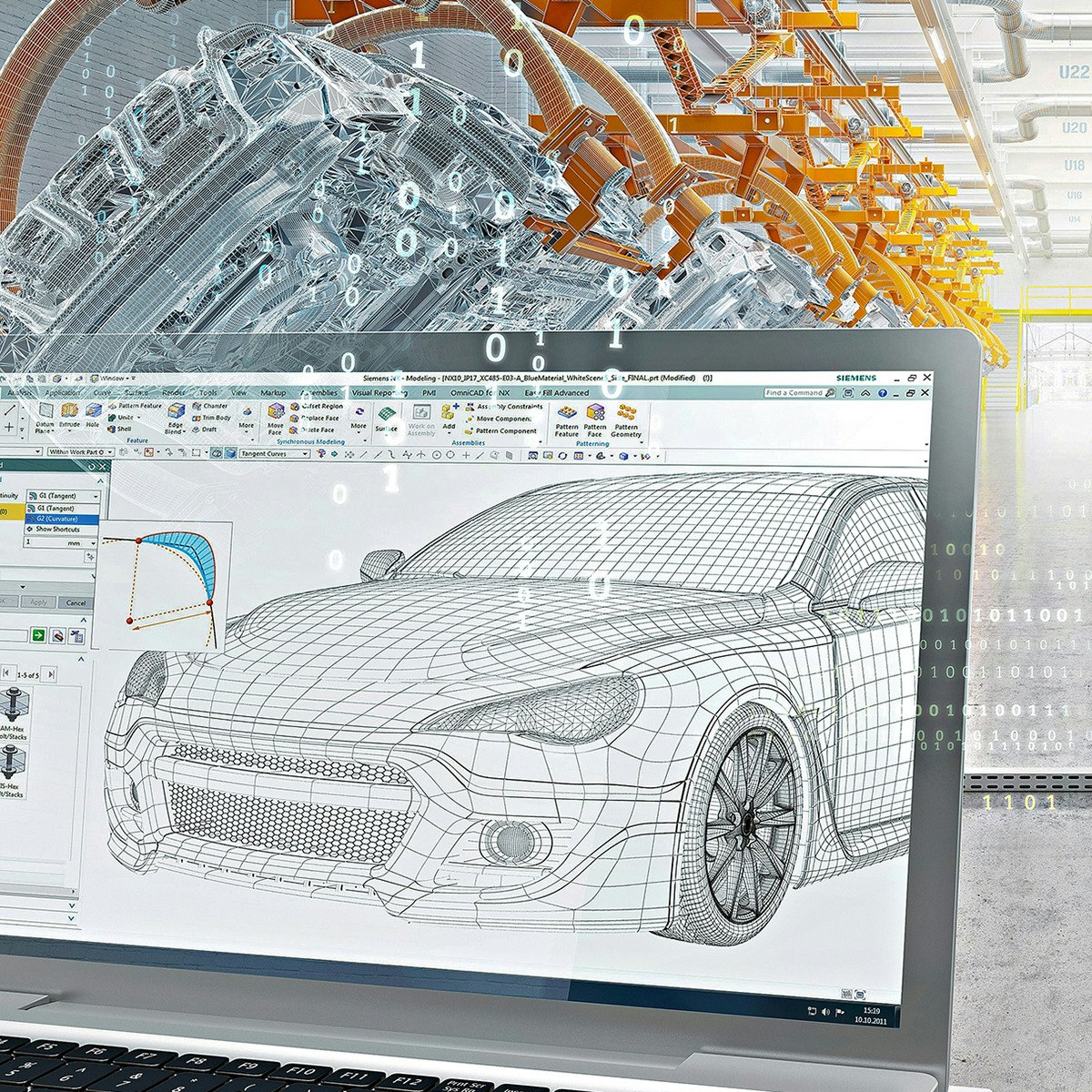

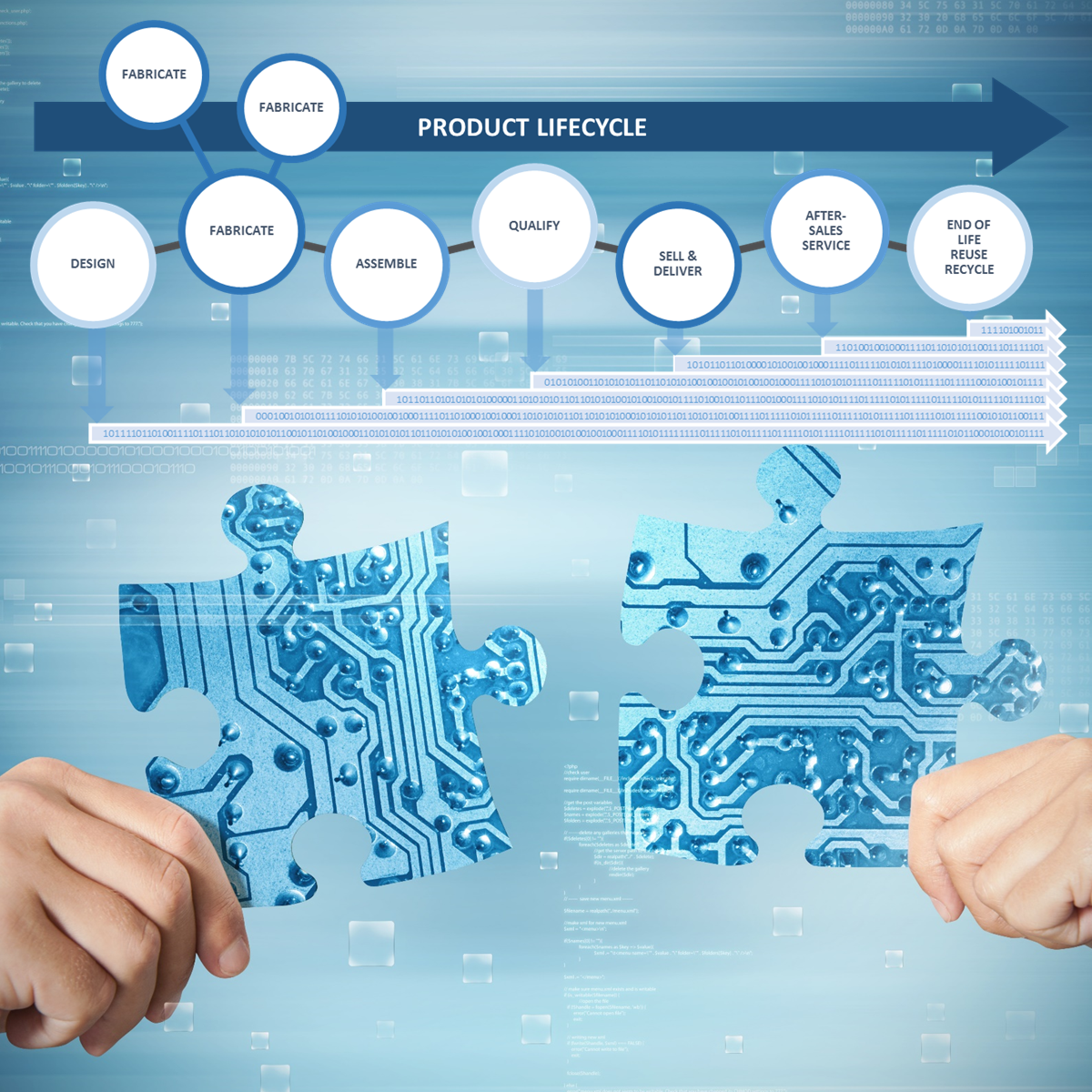

Digital Thread: Implementation

There are opportunities throughout the design process of any product to make significant changes, and ultimately impact the future of manufacturing, by embracing the digital thread. In this course, you will dig into the transformation taking place in how products are designed and manufactured throughout the world. It is the second of two courses that focuses on the "digital thread" – the stream that starts at the creation of a product concept and continues to accumulate information and data throughout the product life cycle.

Hear about the realities of implementing the digital thread, directly from someone responsible for making it happen at a company. Learn how the digital thread can fit into product development processes in an office, on a shop floor, and even across an enterprise. Be prepared to talk about the benefits, and limitations, of enacting it.

Main concepts of this course will be delivered through lectures, readings, discussions and various videos.

This is the third course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturing’s “Fourth Revolution,” aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal. To learn more about the Digital Manufacturing and Design Technology specialization, please watch the overview video by copying and pasting the following link into your web browser: https://youtu.be/wETK1O9c-CA

Major Engineering Projects: Governance, Risk and Scope

Gain confidence when dealing with stakeholders of major projects by learning to identify and manage those that are involved in the project planning and delivery. This course will enable you to explore project governance in theory and practice.

Through real life examples you’ll understand how the critical challenges of the governance in major projects are resolved.

Being able to successfully manage risk and uncertainty in major projects is vital for their delivery. In this course you’ll learn to distinguish between risk and uncertainty and the role of risk register. You’ll identify the unique challenges of scope management in major projects and employ scope management tools and techniques that will facilitate your project planning.

This course explores concepts analysed in the University’s Online MSc in Engineering Management. If you are interested to develop your skills further, take a look at our online degree.

Digital Thread: Components

This course will help you recognize how the "digital thread" is the backbone of the digital manufacturing and design (DM&D) transformation, turning manufacturing processes from paper-based to digital-based. You will have a working understanding of the digital thread – the stream that starts at product concept and continues to accumulate information and data throughout the product’s life cycle – and identify opportunities to leverage it.

Gain an understanding of how "the right information, in the right place, at the right time" should flow. This is one of the keys to unlocking the potential of a digital design process. Acknowledging this will enable you to be more involved in a product’s development cycle, and to help a company become more flexible.

Main concepts of this course will be delivered through lectures, readings, discussions and various videos.

This is the second course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturing’s “Fourth Revolution,” aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal. To learn more about the Digital Manufacturing and Design Technology specialization, please watch the overview video by copying and pasting the following link into your web browser: https://youtu.be/wETK1O9c-CA

Product Development using AutoCAD

By the end of this 1-hour long project-based course, you will be able to design and draw 2D products customized to fit your needs using AutoCAD Design. Throughout the project, you will be equipped with the fundamentals of AutoCAD design, you will be able to draw lines and basic shapes . Afterwards, you will learn how to modify those shapes according to your product drawings.

At the end, you will apply all this to create a 2D spinner drawing. Learning AutoCAD and being professional at it allows you to design a wide range of products, opens up freelancing opportunities for product design and lastly an asset that can be added for your design skills set.

Note: This course works best for learners who are based in the North America region. We’re currently working on providing the same experience in other regions.

Popular Internships and Jobs by Categories

Find Jobs & Internships

Browse

© 2024 BoostGrad | All rights reserved