Back to Courses

Mechanical Engineering Courses - Page 5

Showing results 41-50 of 148

Modern Robotics, Course 4: Robot Motion Planning and Control

Do you want to know how robots work? Are you interested in robotics as a career? Are you willing to invest the effort to learn fundamental mathematical modeling techniques that are used in all subfields of robotics?

If so, then the "Modern Robotics: Mechanics, Planning, and Control" specialization may be for you. This specialization, consisting of six short courses, is serious preparation for serious students who hope to work in the field of robotics or to undertake advanced study. It is not a sampler.

In Course 4 of the specialization, Robot Motion Planning and Control, you will learn key concepts of robot motion generation: planning a motion for a robot in the presence of obstacles, and real-time feedback control to track the planned motion. Chapter 10, Motion Planning, of the "Modern Robotics" textbook covers foundational material like C-space obstacles, graphs and trees, and graph search, as well as classical and modern motion planning techniques, such as grid-based motion planning, randomized sampling-based planners, and virtual potential fields. Chapter 11, Robot Control, covers motion control, force control, and hybrid motion-force control.

This course follows the textbook "Modern Robotics: Mechanics, Planning, and Control" (Lynch and Park, Cambridge University Press 2017). You can purchase the book or use the free preprint pdf. You will build on a library of robotics software in the language of your choice (among Python, Mathematica, and MATLAB) and use the free cross-platform robot simulator V-REP, which allows you to work with state-of-the-art robots in the comfort of your own home and with zero financial investment.

Introduction to High-Throughput Materials Development

This course is an introduction to high-throughput experimental methods that accelerate the discovery and development of new materials.

It is well recognized that the discovery of new materials is the key to solving many technological problems faced by industry and society. These problems include energy production and utilization, carbon capture, tissue engineering, and sustainable materials production, among many others. This course will introduce the learner to a remarkable new approach to materials discovery and characterization: high-throughput materials development (HTMD).

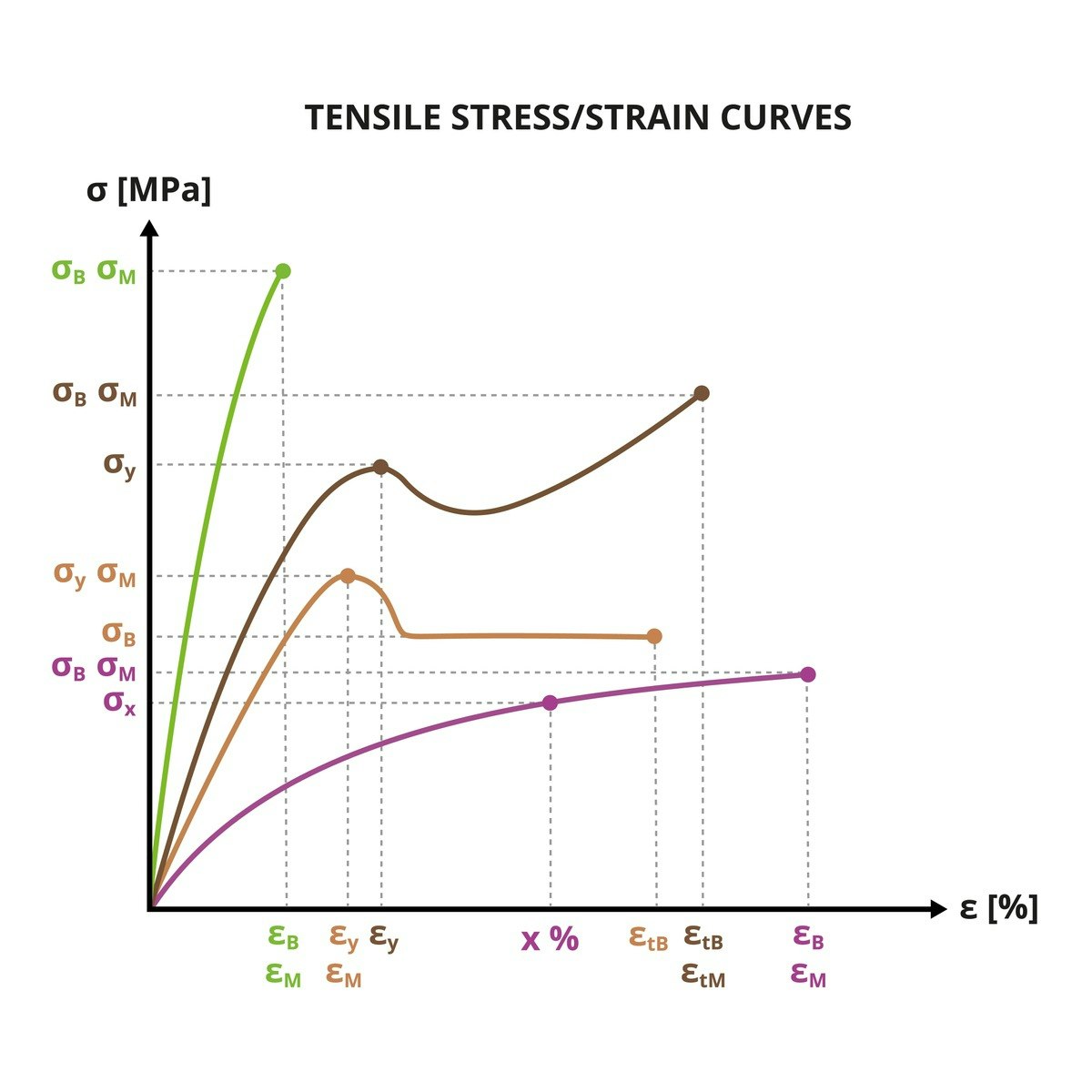

Engineers and scientists working in industry, academic or government will benefit from this course by developing an understanding of how to apply one element of HTMD, high-throughput experimental methods, to real-world materials discovery and characterization problems. Internationally leading faculty experts will provide a historical perspective on HTMD, describe preparation of ‘library’ samples that cover hundreds or thousands of compositions, explain techniques for characterizing the library to determine the structure and various properties including optical, electronic, mechanical, chemical, thermal, and others. Case studies in energy, transportation, and biotechnology are provided to illustrate methodologies for metals, ceramics, polymers and composites.

The Georgia Tech Institute for Materials (IMat) developed this course in order to introduce a broad audience to the essential elements of the Materials Genome Initiative. Other courses will be offered by Georgia Tech through Coursera to concentrate on integrating (i) high-throughput experimentation with (ii) modeling and simulation and (iii) materials data sciences and informatics.

After completing this course, learners will be able to

• Identify key events in the development of High-Throughput Materials Development (HTMD)

• Communicate the benefits of HTMDwithin your organization.

• Explain what is meant by high throughput methods (both computational and experimental), and their merits for materials discovery/development.

• Summarize the principles and methods of high throughput creation/processing of material libraries (samples that contain 100s to 1000s of smaller samples).

• State the principles and methods for high-throughput characterization of structure.

• State the principles and methods for high throughput property measurements.

• Identify when high-throughput screening (HTS) will be valuable to a materials discovery effort.

• Select an appropriate HTS method for a property measurement of interest.

• Identify companies and organizations working in this field and use this knowledge to select appropriate partners for design and implementation of HTS efforts.

• Apply principles of experimental design, library synthesis and screening to solve a materials design challenge.

• Conceive complete high-throughput strategies to obtain processing-structure-property (PSP) relationships for materials design and discovery.

Sensor Manufacturing and Process Control

"Sensor Manufacturing and Process Control" can also be taken for academic credit as ECEA 5343, part of CU Boulder’s Master of Science in Electrical Engineering degree.

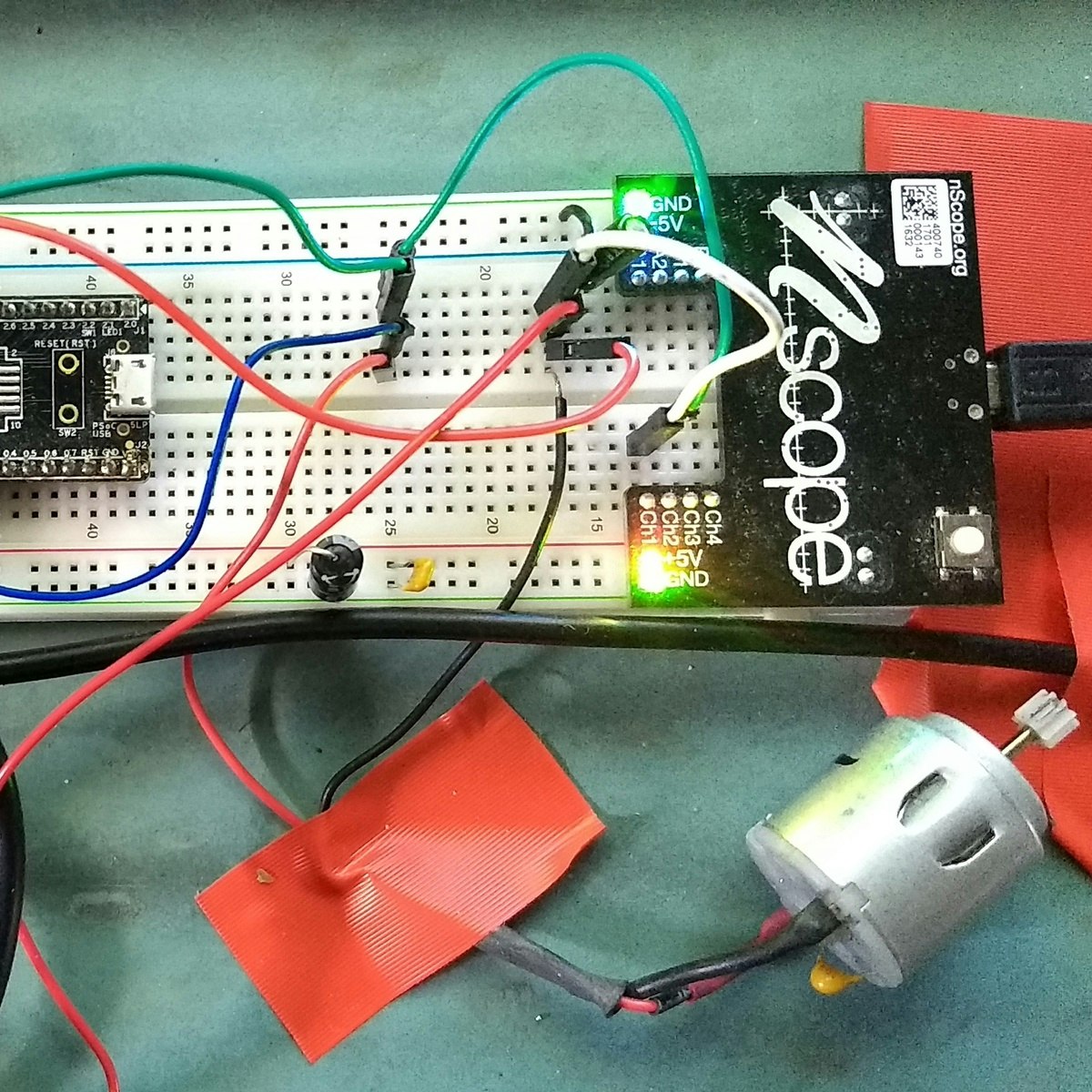

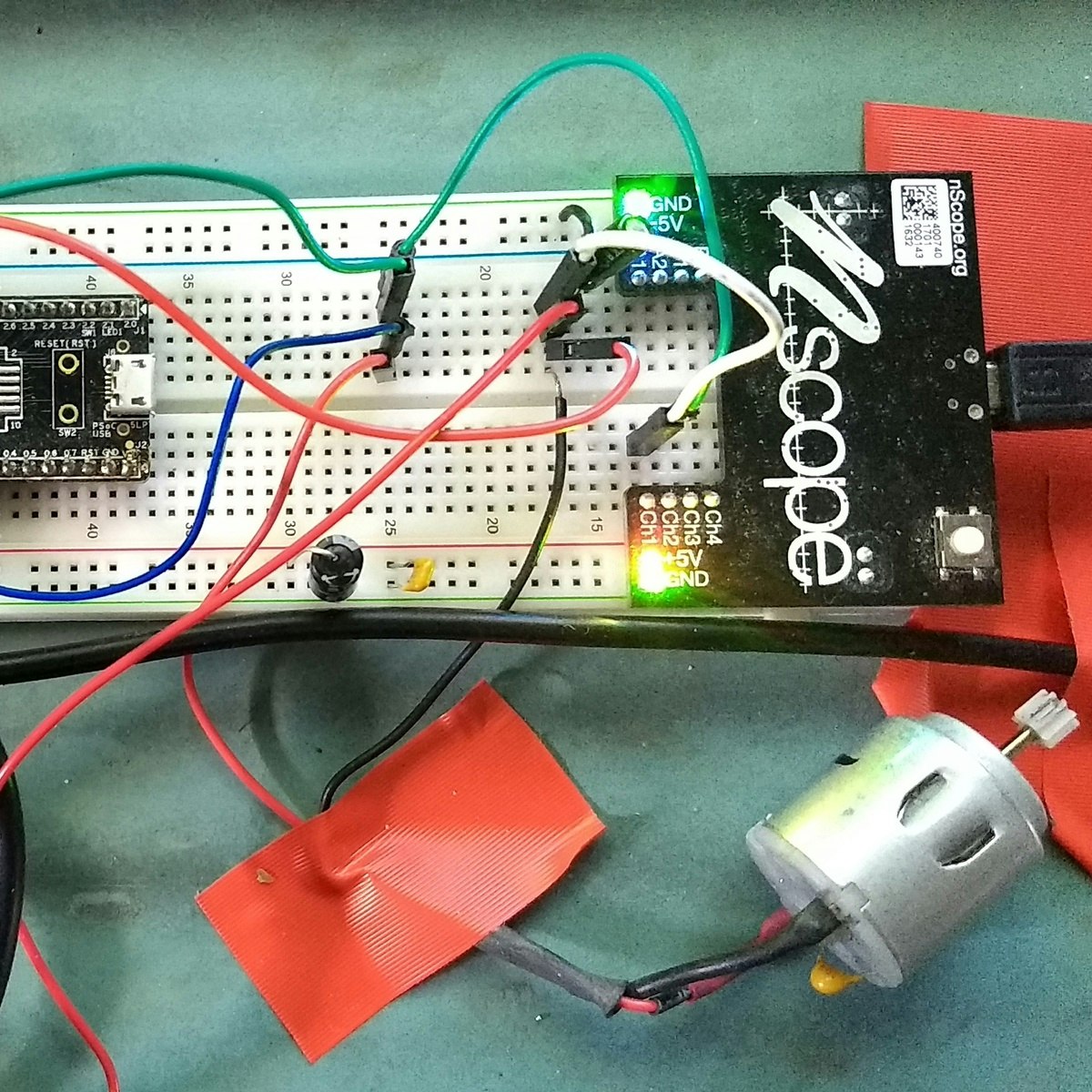

This is our fourth course in our specialization on Embedding Sensor and Motors. To get the most out of this course, you should first take our first course entitled "Sensors and Sensor Circuits", our second course entitled "Motor and Motor Control Circuits", and our third course entitled "Pressure, Force, Motion, and Humidity Sensors". Our first course gives you a tutorial on how to use the hardware and software development kit we have chosen for the lab exercises. Our second and third courses give you three hands-on lab experiments using the kit. This third course assumes that you already know how to use the kit.

You will learn about sensor signal characterization and manufacturing techniques and how to optimize the accuracy of sensors. You will also learn about more advanced sensors, proportional-integral-derivative (PID) control, and how this method is used to give you a closed loop sensor feedback system.

After taking this course, you will be able to:

● Understand how sensor manufacturers characterize and calibrate their sensors.

● Tune a PID control loop and access the PID control function of the Cypress PSoC development kit for a motor control application.

● Understand manufacturing methods used to build electro-mechanical and micro-machined sensors.

You will need to buy the following components to do the two course projects based on the videos in this module. Note that if you have already purchased the PSOC 5LP PROTOTYPING KIT, you do not need to buy it again.

These parts may be purchased off the Digikey web site, www. Digikey.com. Or, you may obtain the specs from the site, and purchase them elsewhere. All are quantity one except for N107-ND where you need three, and 493-15371-ND where you need two.

428-3390-ND

P14355-ND

FQU13N10LTU-ND

N107-ND

1N5393-E3/54GICT-ND

RNF14FTD1K00CT-ND

P0.62W-1BK-ND

493-15371-ND

Additional equipment needed:

• Wire - various gauges and lengths

• Breadboard

• Oscilloscope – suggested models are:

o PICOSCOPE 2204A-D2 available on www.digikey.com or

o Digilent 410-324 | OpenScope MZ available on www.newark.com

Depending on your budget, you can also investigate these models:

o Hantek HT6022BE20MHz - https://www.amazon.com/dp/B009H4AYII

o SainSmart DSO212 - https://www.amazon.com/dp/B074QBQNB7

o PoScope Mega50 USB - https://www.robotshop.com/en/poscope-mega50-usb-mso-oscilloscope.html

o ADALM2000 - https://www.digikey.com/en/products/detail/analog-devices-inc./ADALM2000/7019661

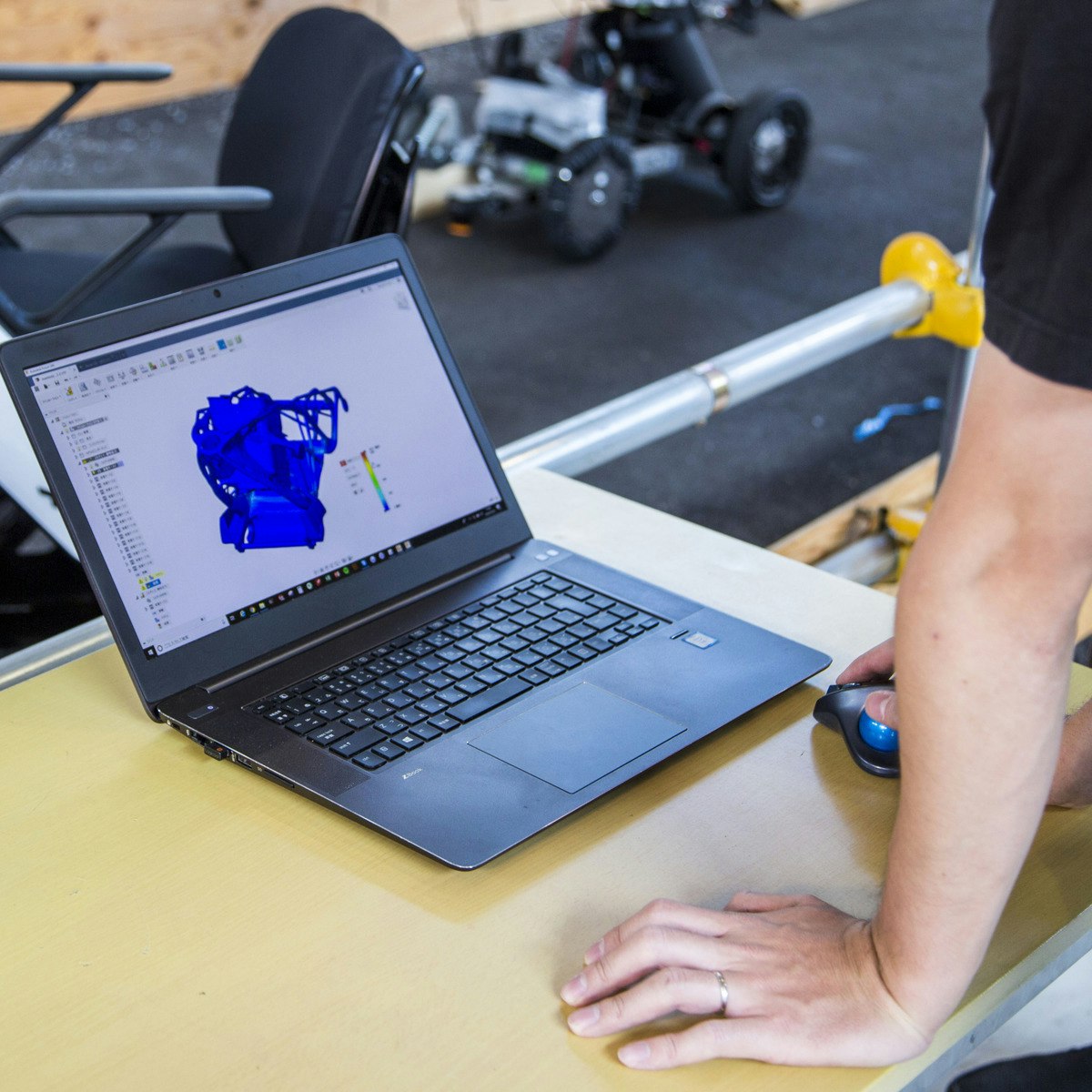

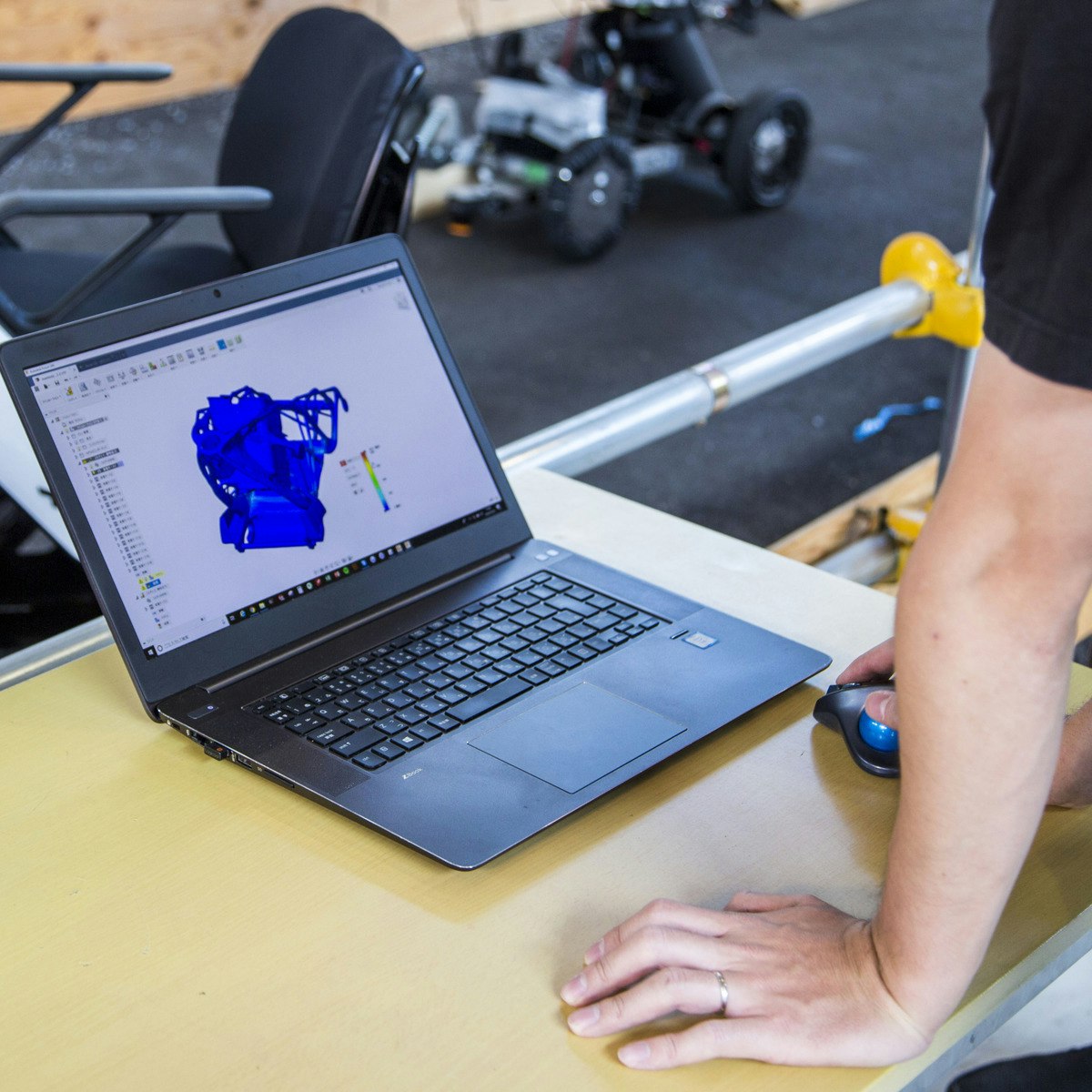

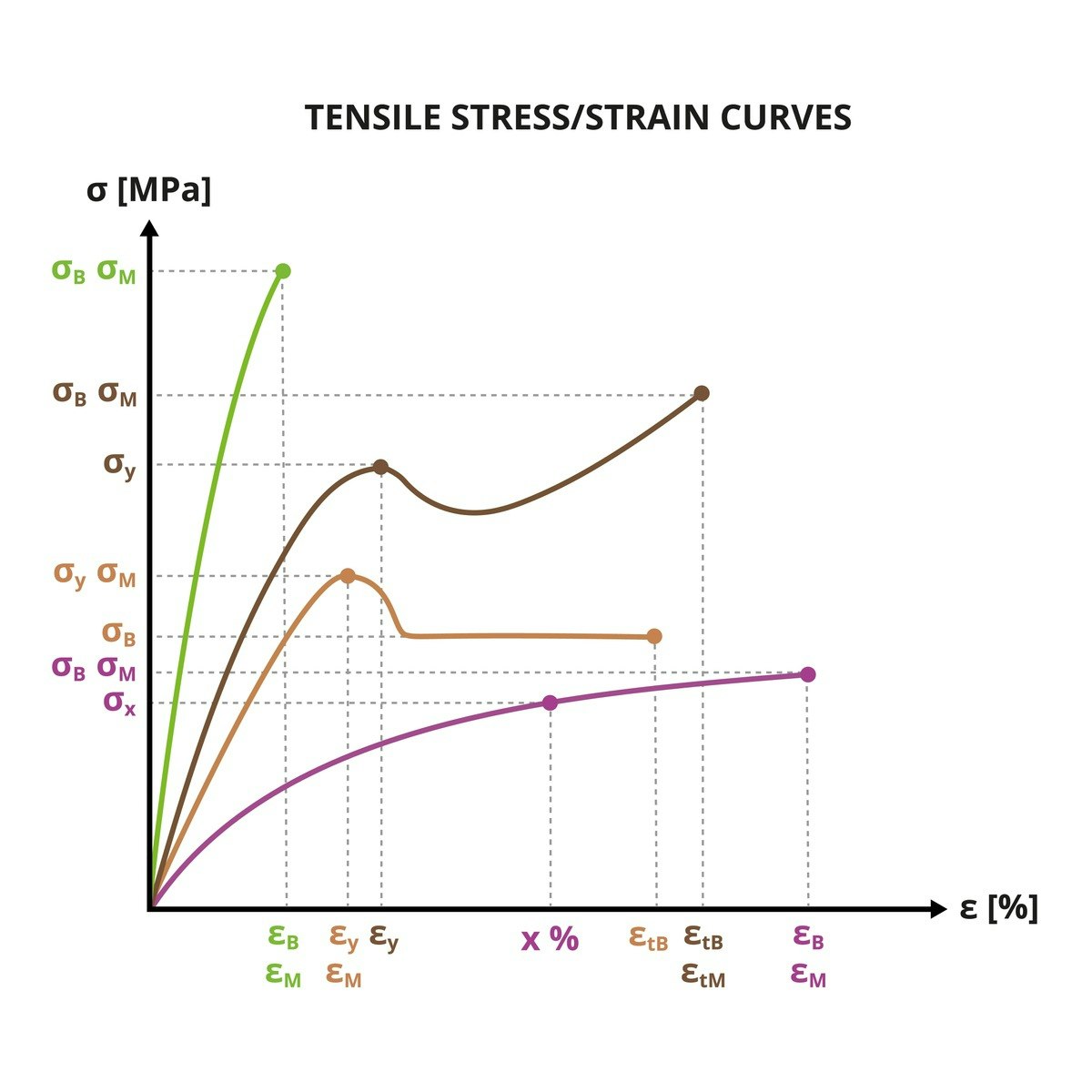

Simulation Analysis for Mechanical Engineers with Autodesk Fusion 360

The foundation of engineering design is often coupled with validation. Simulation is a great tool that allows engineers to test, validate, and modify designs before they become a physical prototype. When used early in the process for simulation driven design and throughout the development process, simulation can help drive the design, make informed design decisions, speed up time to production, and most importantly, identify and eliminate costly design mistakes.

Like any other tool though, it must be used properly to yield the best results. In this course, we’ll explore the usage static stress simulation, shape optimization, thermal and other mechanical simulation types to better understand how we can apply these tools to everyday design problems.

After taking this course, you'll be able to:

- Describe the simulation workflow in Fusion 360.

- Summarize the use cases for various types of simulation studies.

- Demonstrate knowledge and skills in more advanced Fusion 360 CAD and CAE skills.

- Explain and identify simulation results

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

3D CAD Application

Do you want to obtain all the necessary skills of a 3D modeler? Do you want to know how an engineer develop a building model in details? The “3D CAD Application” course, the second course of the new specialization, is coming!

After finishing this course: You will be able to know how to use the SketchUp’s advanced functions by creating 3D building models. You will be able to develop a building as an engineer.

Let’s start the learning journey!

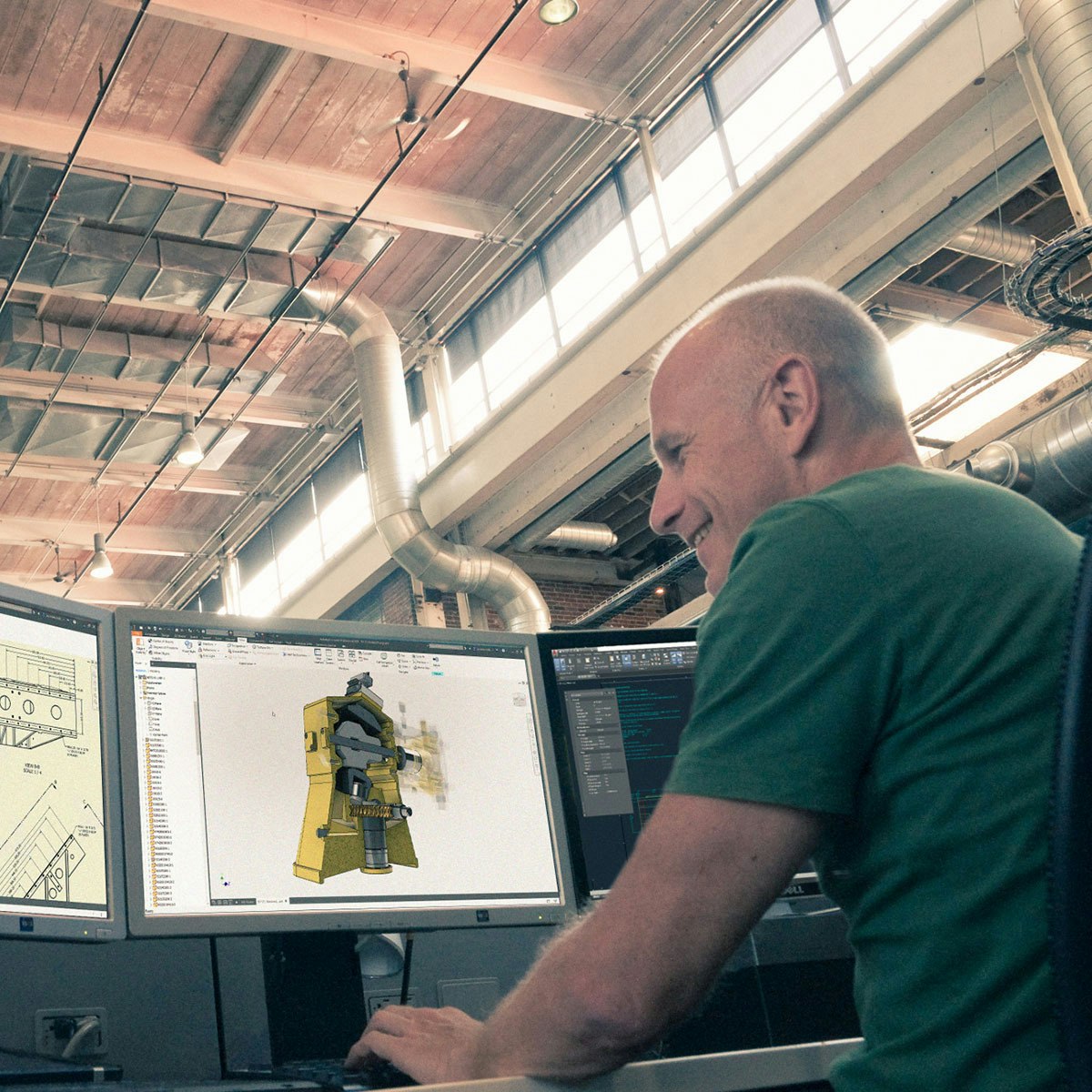

Autodesk Certified Professional: Inventor for Mechanical Design Exam Prep

Prove to potential employers that you’re up to the task by becoming an Autodesk Certified Professional. This online course from Autodesk prepares you by offering an overview of skills that match what is covered in the Autodesk Certified Professional: Inventor for Mechanical Design exam.

Advances in technology are changing the way we work, and the job skills demanded by industry. It’s essential for professionals to be able to demonstrate their knowledge and skills in order to be competitive and meet workforce standards. In this course, we’ll explore the professional skills defined for the Autodesk Certified Professional: Inventor for Mechanical Design exam. Through a series of lessons, practice exercises, challenge assignments, and assessments, we’ll learn and apply the Autodesk Inventor skills covered in the exam to boost your confidence and technical skills in preparation for the exam. At the end of the course, you will have the opportunity to test your knowledge by taking the practice exam that accompanies the course. It’s all about practice and preparation.

About the Autodesk Certified Professional: Inventor for Mechanical Design exam:

The Autodesk Certified Professional: Inventor for Mechanical Design exam is designed for industry professionals who possess advanced skills and can solve complex challenges in workflow and design. A certification at this level demonstrates a comprehensive skill set that provides an opportunity for individuals to stand out in a competitive professional environment. This type of experience typically comes from having worked with the software on a regular basis for at least 2 years, equivalent to approximately 400 hours (minimum) - 1200 hours (recommended), of real-world Autodesk software experience.

The Autodesk Certified Professional (ACP) certifications exams can be taken at a Pearson VUE Testing Center or through OnVUE, Pearson VUE’s online proctored environment. Candidates are given 120 minutes to complete a certification exam and should review the testing center polices and requirements before scheduling. Ready to take the exam? Schedule to take the exam online or find a testing center near you on pearsonvue.com/autodesk.

Looking for more skill-building courses? Check out Autodesk’s additional learning resources to help with your learning journey: https://www.autodesk.com/learning

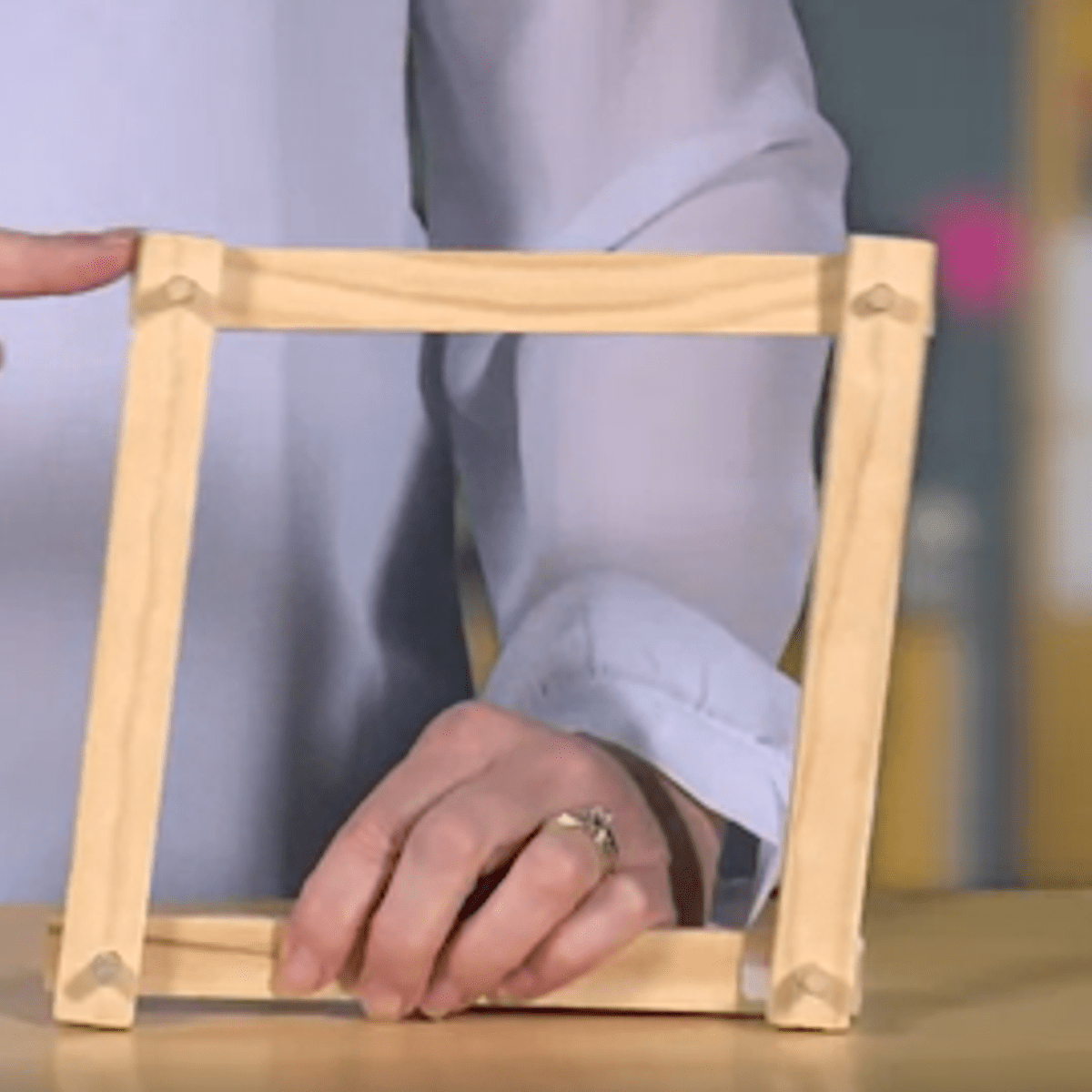

Engineering of Structures: Tension and Compression

This course deals with tension and compression. After going through this course, you will understand why tensegrity structures and sculptures are different from other structures. You will also explore tension and compression in different types of trusses. Additionally you will understand determinacy and realize how it applies to trusses. The first module introduces you to the concept of tension and compression. The second module explores topics such as tensegrity structure, trusses, and determinacy. After finishing this module, you will also be able to calculate the force in members of a truss. The third module explores how to build a truss bridge.

Phase Diagrams

This course will explore higher-level details about phase diagrams, including the Fe-Fe3C phase diagram. We will use the Fe-Fe3C phase diagram to predict the possible phases and microstructures of a steel alloy based on its composition.

Introduction to CAD, CAM, and Practical CNC Machining

This course introduces you to the foundational knowledge in computer-aided design, manufacture, and the practical use of CNC machines. In this course we begin with the basics in Autodesk® Fusion 360™ CAD by learning how to properly sketch and model 3D parts. Before we program any toolpaths, we’ll explore CNC machining basics to ensure we have the ground level foundational knowledge needed to effectively define toolpaths. Finally, we explore the basics of setting up a CAM program and defining toolpaths to cut simple geometry. This is the same basic process that gets repeated for the design and manufacture of any part and is a critical step in learning and understanding the process.

Want to take your learning to the next level? Complete the Autodesk CAD/CAM for Manufacturing Specialization, and you’ll unlock an additional Autodesk Credential as further recognition of your success! The Autodesk Credential comes with a digital badge and certificate, which you can add to your resume and share on social media platforms like LinkedIn, Facebook, and Twitter. Sharing your Autodesk Credential can signal to hiring managers that you’ve got the right skills for the job and you’re up on the latest industry trends like generative design.

Enroll in the Specialization here: https://www.coursera.org/specializations/autodesk-cad-cam-manufacturing

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

3D Printing Capstone

The capstone will integrate the learning acquired from the four courses in the 3D Printing Specialization through a hands-on project. This project will enable you to turn an idea into an object using the knowledge and skills acquired through the other courses. Specifically, you will be guided through a step-by-step process in which you imagine, design, make, and share a 3D printed object. Thus, through this capstone, you will be able to put course concepts into action and utilize the skills that you have acquired throughout the Specialization. In addition, you will be able to obtain an actual 3D print of the object you design at a discounted price through our corporate partners, 3D Hubs and Shapeways.

If you enjoy this business course and are interested in an MBA, consider applying to the iMBA, a flexible, fully-accredited online MBA at an incredibly competitive price offered by the University of Illinois. For more information, please see the Resource page in this course and onlinemba.illinois.edu.

Popular Internships and Jobs by Categories

Find Jobs & Internships

Browse

© 2024 BoostGrad | All rights reserved