Back to Courses

Mechanical Engineering Courses - Page 15

Showing results 141-148 of 148

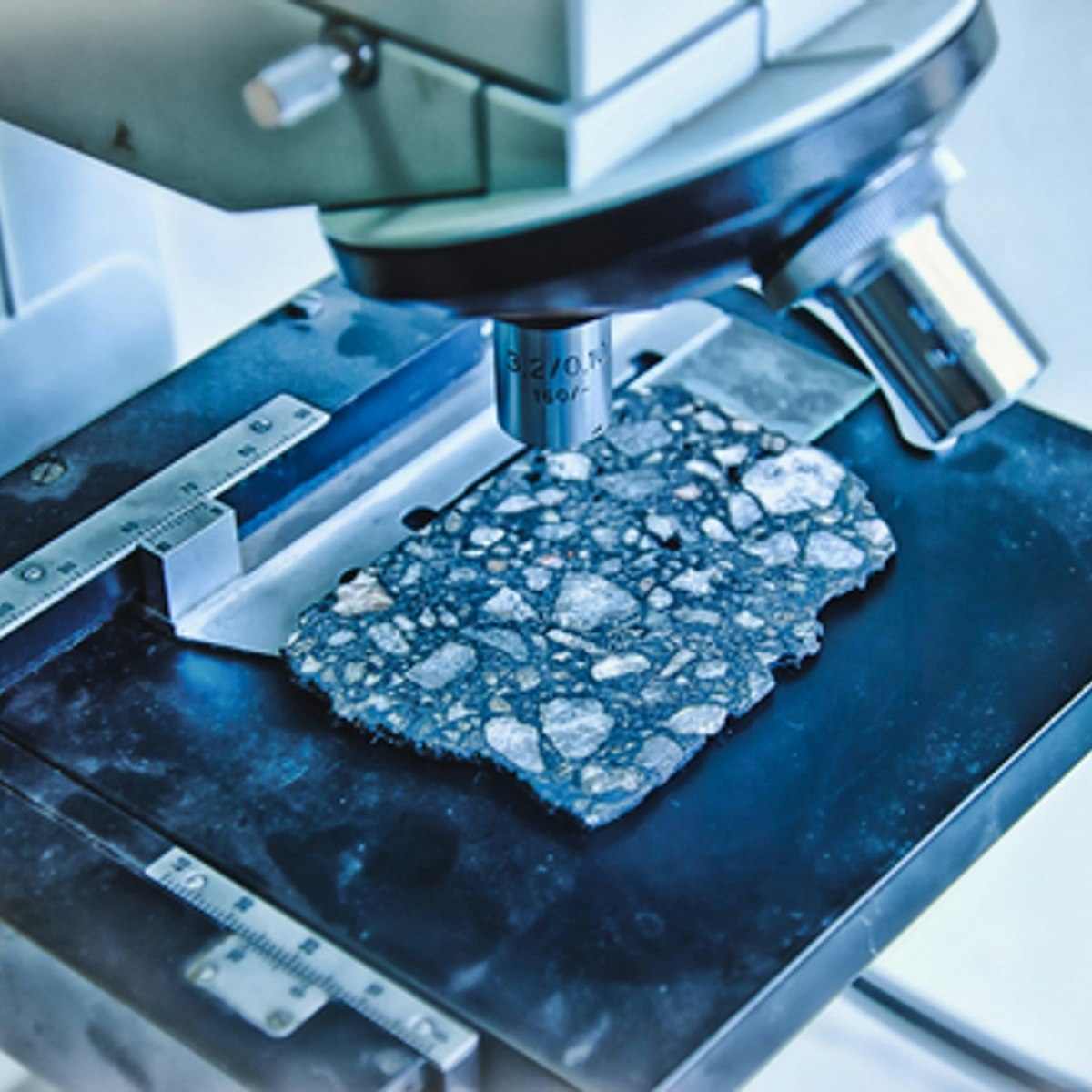

Material Behavior

Have you ever wondered why ceramics are hard and brittle while metals tend to be ductile? Why some materials conduct heat or electricity while others are insulators? Why adding just a small amount of carbon to iron results in an alloy that is so much stronger than the base metal? In this course, you will learn how a material’s properties are determined by the microstructure of the material, which is in turn determined by composition and the processing that the material has undergone.

This is the first of three Coursera courses that mirror the Introduction to Materials Science class that is taken by most engineering undergrads at Georgia Tech. The aim of the course is to help students better understand the engineering materials that are used in the world around them. This first section covers the fundamentals of materials science including atomic structure and bonding, crystal structure, atomic and microscopic defects, and noncrystalline materials such as glasses, rubbers, and polymers.

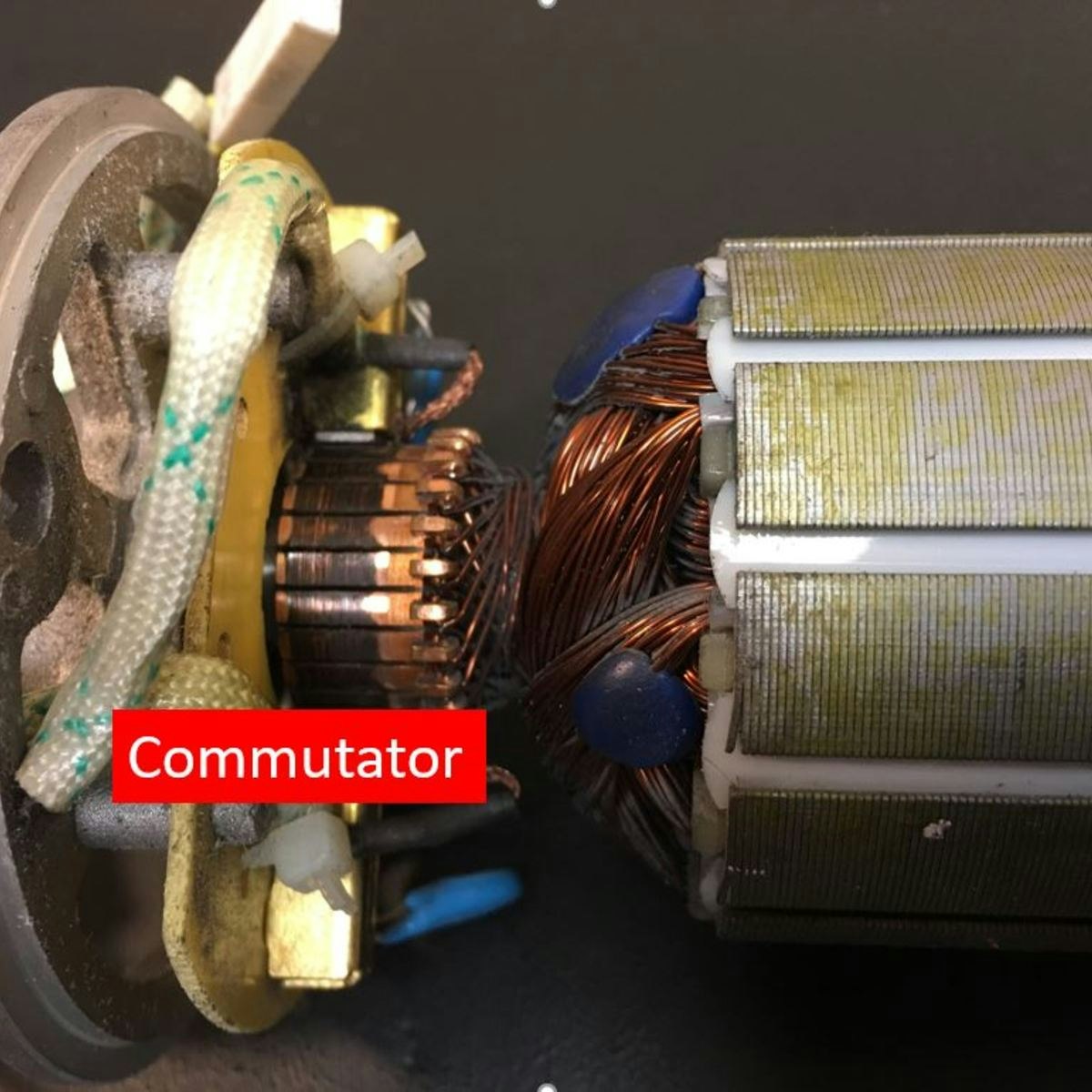

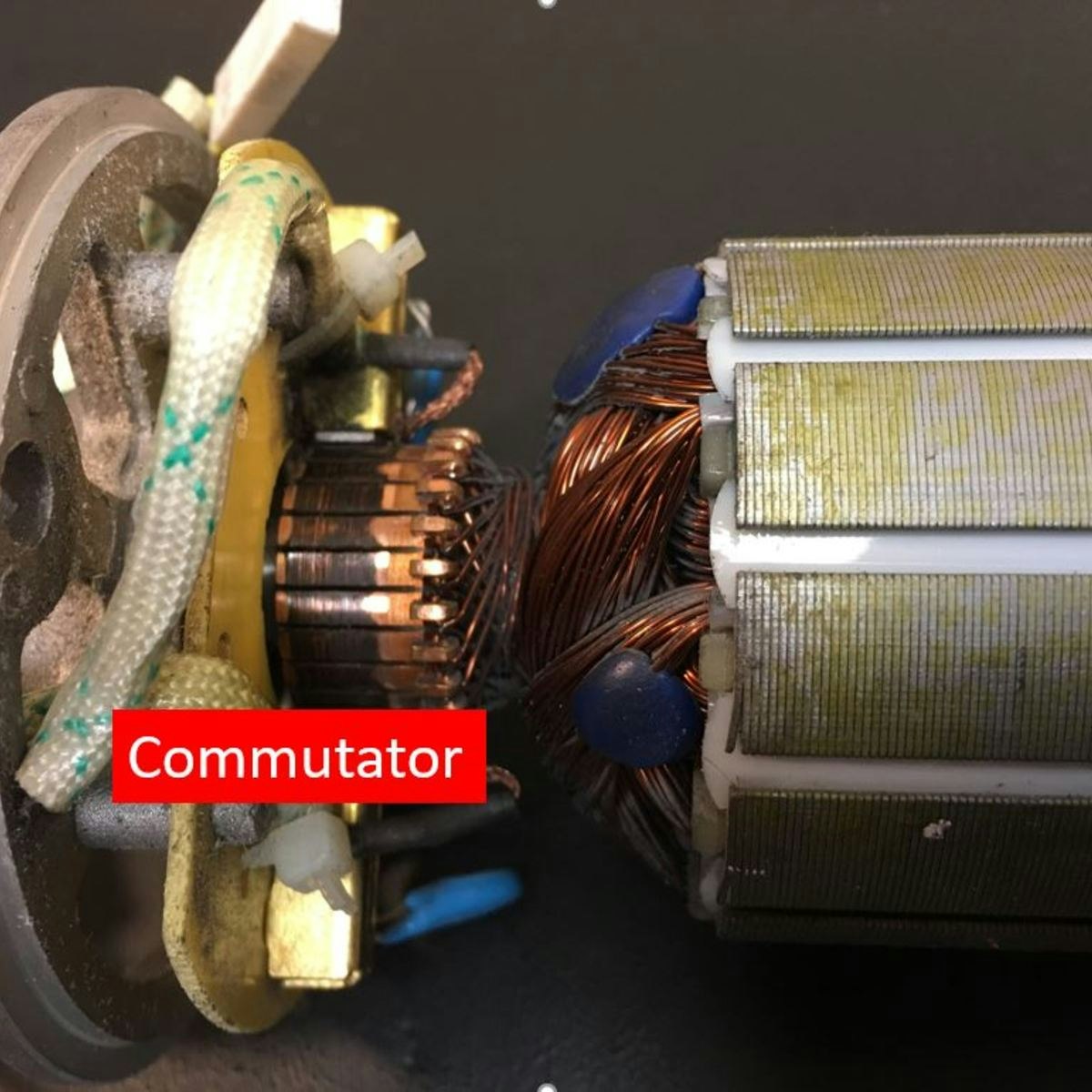

Motors and Motor Control Circuits

This course can also be taken for academic credit as ECEA 5341, part of CU Boulder’s Master of Science in Electrical Engineering degree.

This is our second course in our specialization on Embedding Sensor and Motors. To get the most out of this course, you should first take our first course entitled Sensors and Sensor Circuits. Our first course gives you a tutorial on how to use the hardware and software development kit we have chosen for the lab exercises. This second course assumes that you already know how to use the kit.

After taking this course, you will be able to:

● Understand how to specify the proper AC or DC motor for a machine design.

● Integrate the motor to a machine, based on analysis of motor equations for voltage, current, torque and speed.

● Implement the motor and accompanying rotary sensor into a motor control circuit in both hardware and software.

● Add a motor and motor control circuit into a microprocessor based development kit.

● Create hardware and firmware to process motor feedback data to a microprocessor for further evaluation.

You will need to buy the following components to do the two course projects based on the videos in this module. Note that if you have already purchased the PSOC 5LP PROTOTYPING KIT, you do not need to buy it again.

These parts may be purchased off the Digikey web site, www. Digikey.com. Or, you may obtain the specs from the site, and purchase them elsewhere.

These are the part numbers for the above table, the lab on Motor Voltage and Current Measurement. You can copy and paste them into the search engine on the Digikey web site. You need one of each except for the AA batteries (N107-ND), which you would need 3.

428-3390-ND

P14355-ND

FQU13N10LTU-ND

N107-ND

1N5393-E3/54GICT-ND

RNF14FTD1K00CT-ND

P0.62W-1BK-ND

Additional equipment needed:

• Wire - various gauges and lengths

• Breadboard

• Oscilloscope – suggested models are:

o PICOSCOPE 2204A-D2 available on www.digikey.com or

o Digilent 410-324 | OpenScope MZ available on www.newark.com

Depending on your budget, you can also investigate these models:

o Hantek HT6022BE20MHz - https://www.amazon.com/dp/B009H4AYII

o SainSmart DSO212 - https://www.amazon.com/dp/B074QBQNB7

o PoScope Mega50 USB - https://www.robotshop.com/en/poscope-mega50-usb-mso-oscilloscope.html

o ADALM2000 - https://www.digikey.com/en/products/detail/analog-devices-inc./ADALM2000/7019661

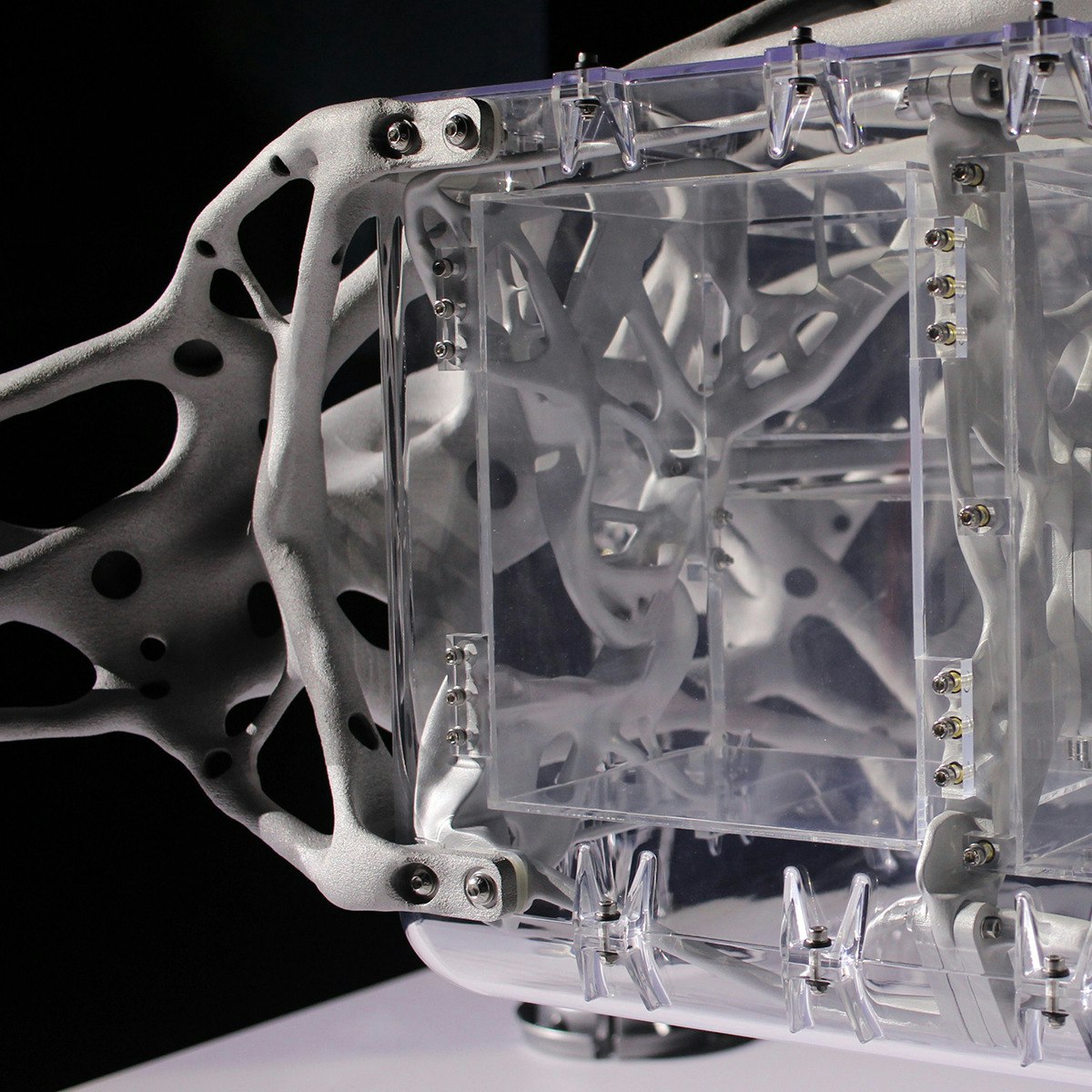

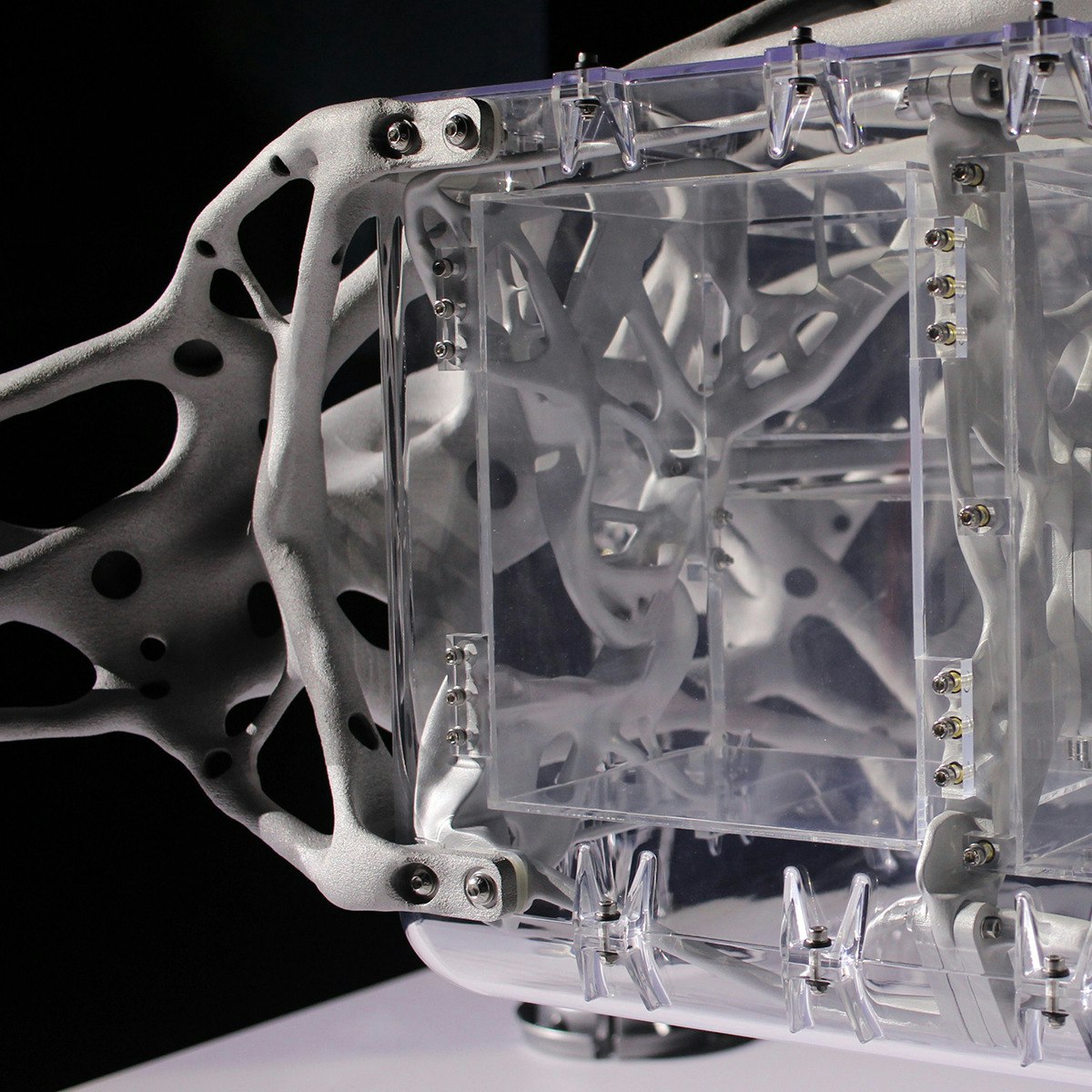

Generative Design for Additive Manufacturing

This course introduces you to one of the more common applications of generative design: Additive Manufacturing or 3D printing as it’s also known. In this course, we explore the basics of geometry creation and the mindset shift needed to build a generative design—a deeper understanding of generative design, its parameters, and how to work with the results specifically aimed at making a 3D printed metal part. We develop insightful understanding of the generative workflow by exploring Autodesk® Fusion 360™ tools and combining them with the creative process of taking an idea to a 3D model. We'll learn how to focus on where a design is and isn’t and apply the generative design thinking process to define a study as we take a deeper dive into Fusion 360.

You’ll need a paid subscription to Fusion 360 to complete the assignments in this course. Be sure to review your access or payment options before enrolling: https://www.autodesk.com/products/fusion-360

Want to take your learning to the next level? Complete the Autodesk Generative Design for Manufacturing Specialization, and you’ll unlock an additional Autodesk Credential as further recognition of your success! The Autodesk Credential comes with a digital badge and certificate, which you can add to your resume and share on social media platforms like LinkedIn, Facebook, and Twitter. Sharing your Autodesk Credential can signal to hiring managers that you’ve got the right skills for the job and you’re up on the latest industry trends like generative design.

Enroll in the Specialization here: https://www.coursera.org/specializations/autodesk-generative-design-manufacturing

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

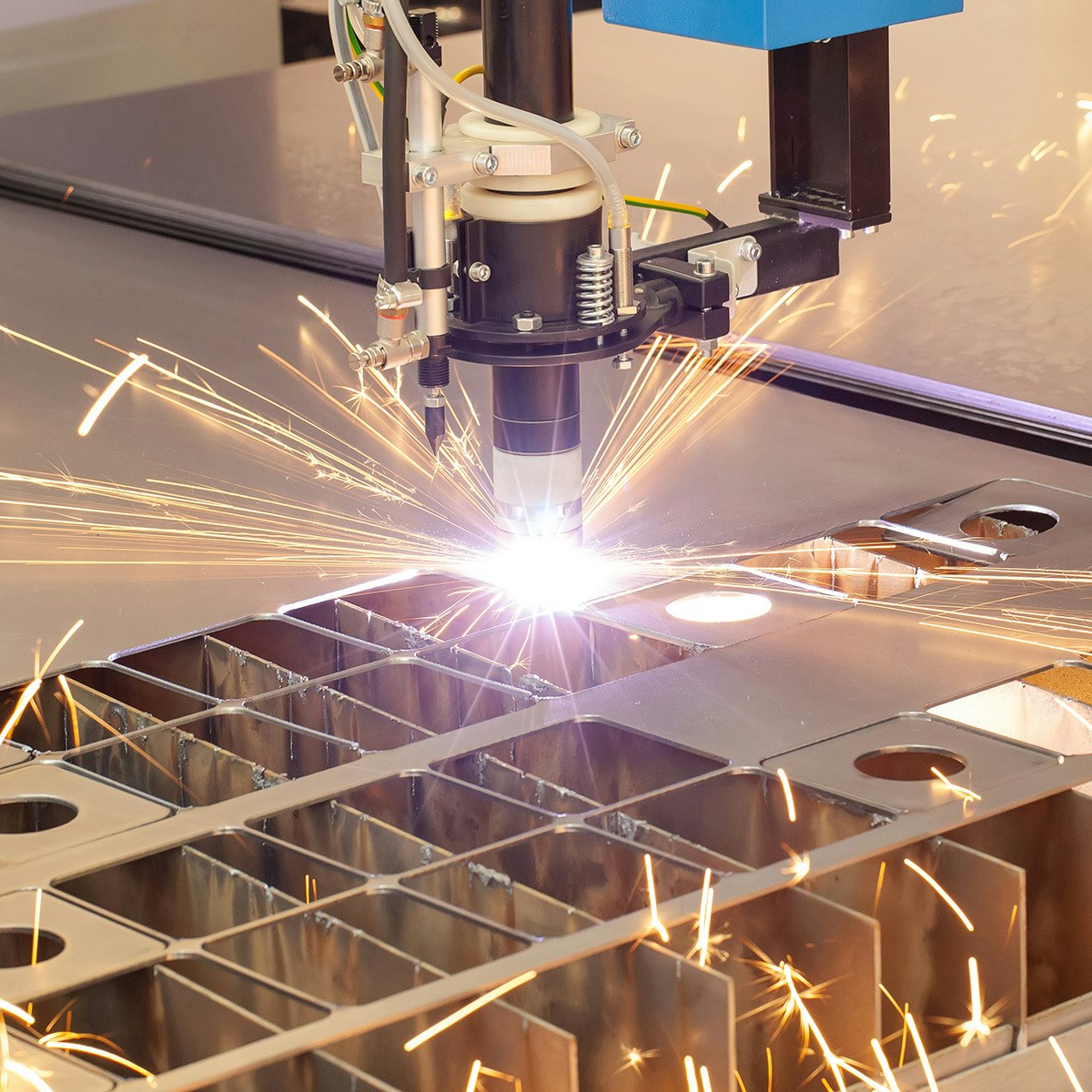

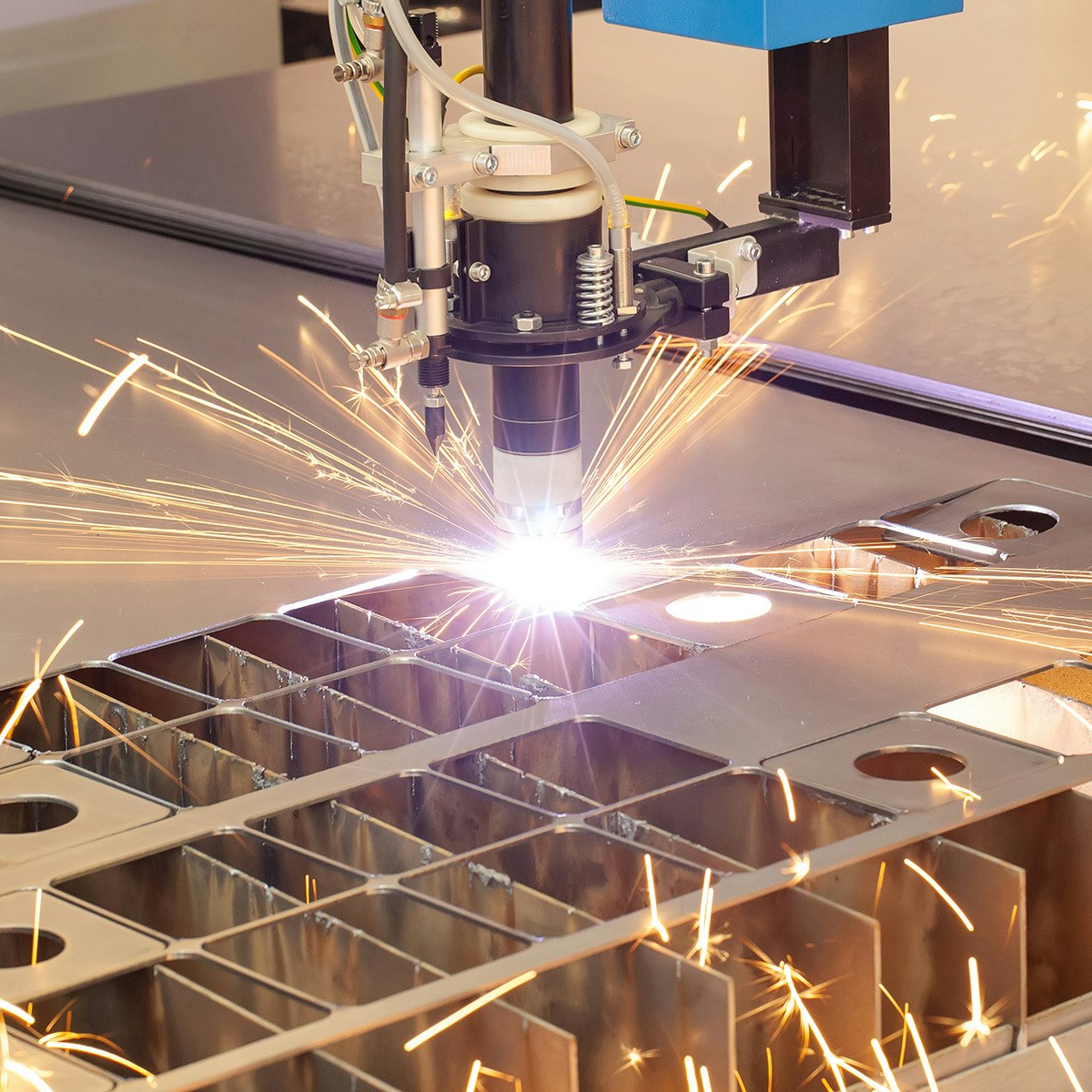

Digital Manufacturing & Design

This course will expose you to the transformation taking place, throughout the world, in the way that products are being designed and manufactured. The transformation is happening through digital manufacturing and design (DM&D) – a shift from paper-based processes to digital processes in the manufacturing industry. By the end of this course, you’ll understand what DMD is and how it is impacting careers, practices and processes in companies both large and small.

You will gain an understanding of and appreciation for the role that technology is playing in this transition. The technology we use every day – whether it is communicating with friends and family, purchasing products or streaming entertainment – can benefit design and manufacturing, making companies and workers more competitive, agile and productive. Discover how this new approach to making products makes companies more responsive, and employees more involved and engaged, as new career paths in advanced manufacturing evolve.

Main concepts of this course will be delivered through lectures, readings, discussions and various videos.

This is the first course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturing’s “Fourth Revolution,” aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal. To learn more about the Digital Manufacturing and Design Technology specialization, please watch the overview video by copying and pasting the following link into your web browser: https://youtu.be/wETK1O9c-CA

Engineering Design Process with Autodesk Fusion 360

This course provides a deeper exploration of mechanical assemblies and simulation, which are key engineering features of the design and manufacturing process. The foundation of engineering design is exploration and iteration. Design is rarely a perfectly linear and straightforward process. In this course, we'll explore mechanical assembly design and simulation, focusing on testing and improving design components and performance. As we move through design assumptions, testing, and refining design ideas, we'll come closer to a final design, while developing a deeper knowledge in Autodesk® Fusion 360™ for simulating and analyzing product functionality.

After completing this course, you will be able to:

• Describe the engineering design process and workflow in Fusion 360.

• Summarize the trends that are influencing the design industry.

• Demonstrate knowledge and skills in more advanced Fusion 360 CAD and simulation skills

Looking for Autodesk Fusion 360 certification prep courses? Check out additional learning resources to help you uplevel your skills: https://www.autodesk.com/learning

Roadmap to Success in Digital Manufacturing & Design

Learners will create a roadmap to achieve their own personal goals related to the digital manufacturing and design (DM&D) profession, which will help them leverage relevant opportunities. The culminating project provides a tangible element to include in their professional portfolios that showcases their knowledge of Industry 4.0.

This project is part of the Digital Manufacturing and Design Technology specialization that explores the many facets of manufacturing’s “Fourth Revolution,” aka Industry 4.0. To learn more about the specialization and its courses, please watch the overview video by copying and pasting the following link into your web browser: https://youtu.be/wETK1O9c-CA

Modeling and Control of Single-Phase Rectifiers and Inverters

This course can also be taken for academic credit as ECEA 5709, part of CU Boulder’s Master of Science in Electrical Engineering degree.

This is Course #5 in the Modeling and Control of Power Electronics Specialization. The course is focused on modeling and control of grid-tied power electronics. Upon completion of the course, you will be able to understand, analyze, model, and design low-harmonic rectifiers and inverters interfacing dc loads or dc power sources, such as photovoltaic arrays, to the single-phase ac power grid.

We strongly recommend students complete the CU Boulder Power Electronics Specialization as well as Courses #1 (Averaged-Switch Modeling and Simulation) and #4 (Current-Mode Control) before enrolling in this course (the course numbers provided below are for students in the CU Boulder's MS-EE program):

● Introduction to Power Electronics (ECEA 5700)

● Converter Circuits (ECEA 5701)

● Converter Control (ECEA 5702)

● Averaged-Switch Modeling and Simulation (ECEA 5705)

● Current-Mode Control (ECEA 5708)

After completing this course, you will be able to:

● Understand the operating principles of low-harmonic, high power factor rectifier and inverters

● Model and design current shaping and voltage control loops in power factor correction (PFC) rectifiers

● Model and design control loops in single-phase dc-to-ac inverters

● Design photovoltaic power systems tied to the single-phase ac power grid

● Use computer-aided tools and simulations to verify the design of rectifiers and inverters

Shape and Property Control of Metals I & II

This course introduces students to the basic concepts of shaping materials and their impacts on properties and structure. An introduction to the fundamentals of diffusion in a solid follows. We present different types of diffusion mechanisms and their dependence on temperature. The role of dislocation on mechanical properties and how it can be used to strengthen materials will be shown.

Popular Internships and Jobs by Categories

Find Jobs & Internships

Browse

© 2024 BoostGrad | All rights reserved